- Stock: In Stock

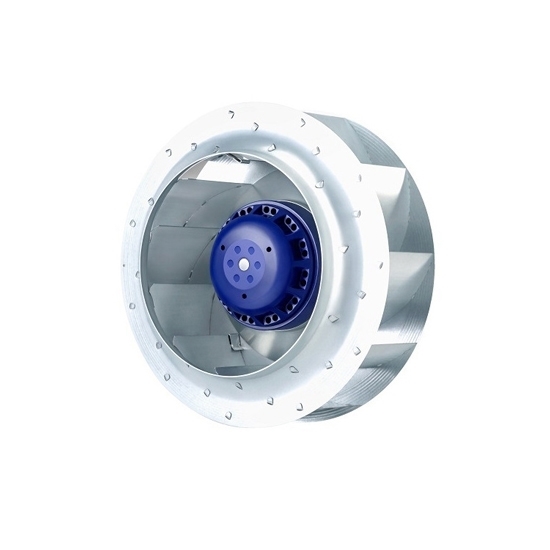

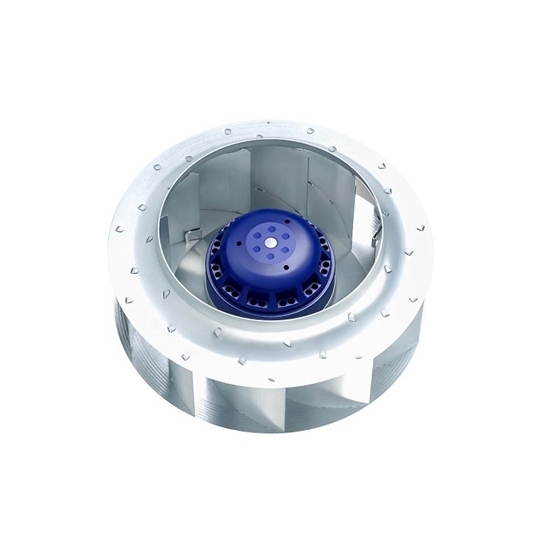

- Model: RDDLZ-BCCF-AC280

- Weight: 1.00

- SKU: RDDLZ-BCCF-AC280

Available Options

280mm AC backward inclined centrifugal fan is characterized by its backward curved blades, the fan generates high airflow and pressure with relatively low power consumption. The backward curve blade design ensures that the fan operates quietly and with reduced turbulence compared to other blade types.

Specification

| Model | RDDLZ-BL-B280A-2E-D01-01 |

| Operating Voltage | 184~270V AC |

| Shaft Power | 280W |

| Motor Power | 280W |

| Impeller Diameter | 280mm |

| Speed | 2400rpm |

| Air Volume | 2000m3/h (1200 cfm) |

| Speed Regulation | 0~10VDC / PWM |

| Signal Output | FG (Frequency Generator) |

| Air Pressure | 680PA |

| Impeller Material | Metal |

| Casing Material | SPCC+S45C |

| Rotation Direction | Clockwise CW (from the rotor end) |

| Number of Impellers | 38 |

| Operation Mode | S1 |

| Bearing | Ball Bearing |

| Operating Temperature | -25~60℃ |

| Operating Humidity | 5%~90% RH |

| Average Life | 50,000 Hours(L10) |

| Motor Protection | Thermal Protection, Soft Start Protection, Stall Protection, Undervoltage Protection, Overvoltage Protection, Overcurrent Protection |

| Performance | Low Noise Fan |

| Protection Level | IP44 |

| Insulation Level | F |

| Certificate | CCC, RoHS |

| Dimensions (L*W*H) | 280*280*125mm |

Dimension (Unit: mm)

Performance Curve

Detail

Tips: What is an AC backward curved centrifugal fan?

An AC backward curved centrifugal fan is a type of air-moving device used in various industrial and commercial applications. It features blades that curve backward relative to the direction of rotation. This design is optimal for creating high air pressure and efficiently moving air or gases through a system.

In operation, air is drawn into the center of the fan, or the "impeller," and then directed outward by the backward-inclined blades. This blade design minimizes turbulence and reduces noise while enhancing the fan's efficiency and stability. These fans are typically used in HVAC systems, air handling units, and other ventilation systems where a strong, consistent airflow is required. Their robust construction and energy-efficient performance make them suitable for demanding environments.