- Stock: In Stock

- Model: RDDLZ-SPINDLE-A1500

- Weight: 1.00

- SKU: RDDLZ-SPINDLE-A1500

Available Options

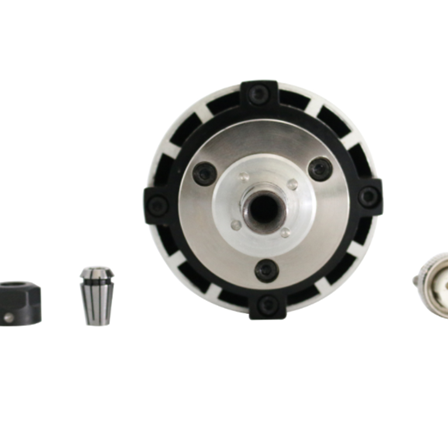

1500W CNC spindle motor for sale at affordable price, 24000 rpm speed, 0.58 Nm torque, 400Hz frequency, 3 phase 220V AC operating voltage, ER11 (φ3.175 mm - φ7 mm) collet.

Feature

- Spindle motor with air cooling fan and ER11 collet ensures smooth running.

- Fast response, strong overload capacity, low noise, and high mechanical precision.

- High quality 3 pcs bearings (7002Cx2 + 7002Cx1), runout off less than 0.01mm, tapered bore less than 0.005mm.

- P4 grade ceramic ball bearings are used as spindle bearings, which improves the service life under high-speed revolution.

- Lubricated with grease, which is resistant to 200 degrees high temperature.

- Tight sealing and two-layer dustproof design.

Application

This series of air-cooled electric spindle motors mainly match with variable frequency drives or engraving machines, and CNC router machines, and are used for high-speed profiling, drilling, cutting, engraving, and groove milling of wood, metal, plastics, foam, rubber, and other materials.

Note: The spindle motor and VFD shall be suitable with each other. The specifications and parameter settings of the VFD shall match the nominal parameters of the spindle motor. Otherwise, it will burn the spindle motor if the settings are not correct.

Specification

| Model | STF80-1.5-ER11 |

| Matched VFD Model | GK3000-2S0022 (3 hp single to three phase VFD) GK3000-4T0022G (3 hp three phase VFD) |

| Power | 1.5 kW |

| Phase | Three phase |

| Speed | 24000 rpm |

| Voltage | 3-phase 220V±10% AC Note: (The default voltage of the matching VFD is consistent with the motor voltage) |

| Current | 6.0A |

| Frequency | 400Hz |

| Torque | 0.58 Nm |

| Number of Pole | 2 poles |

| Cooling Type | Air-cooled |

| Installation Method | Horizontally or Vertically (When the motor is installed, the radial runout standard is required to be within 5um, and the chuck is generally 10um-15um.) |

| Lubrication | Grease |

| Thermal Class | Class F |

| Protection Class | IP50 |

| Certification | CE |

| Warranty | Bearings for half a year, other parts for one year |

| Joint of Nose | ER11 (φ3.175 mm - φ7 mm) |

| Bearings Type | 7002C P4*2 & 7002C P4*1 |

| Application | Woodworking & Plastic |

| Weight | 3.8 kg |

| Download Attachments | 1500W Air Cooled Spindle Motor CAD Drawings |

Details

Tips: 1.5kW CNC Spindle Motor Using Case

A customer inquired that his engraving machine has been purchased for 10 years, and it has been used normally. However, during recent use, the 1.5kW spindle motor of the engraving machine stopped suddenly and the VFD displayed ERR 01. Sometimes the motor is energized with a buzzing sound, but it does not rotate. After the situation occurred, the client did not understand the reason, so consulted RDDLZ. Below is a summary of the reasons and solutions for the spindle of the CNC engraving machine to stop, for the reference of the majority of users:

1. The three-wire cable plug-in connecting the spindle motor to the inverter is disconnected. Solution: Reconnect or reconnect and try again.

2. The lead wire in the spindle motor of the engraving machine is open welding. Confirmation method: Measure the resistance between the three cores of the spindle motor socket with a multimeter. Solution: Remove the socket and re-solder the open wire.

3. The three-wire cable connecting the spindle motor to the frequency inverter is disconnected. Confirmation method: Measure the resistance between the plugs at both ends of the cable with a multimeter. Solution: Connect the broken wire or replace the wire.