- Stock: In Stock

- Model: RDDLZ-LDG-60A

- Weight: 1.00

- SKU: RDDLZ-LDG-60A

Available Options

Single axis laser diameter gauges have high accuracy and precision, often capable of measuring diameters down to micrometer-level tolerances. Laser diameter measuring devices are widely used in various industries such as wire and cable manufacturing, metalworking, plastics extrusion, and textile production.

Features

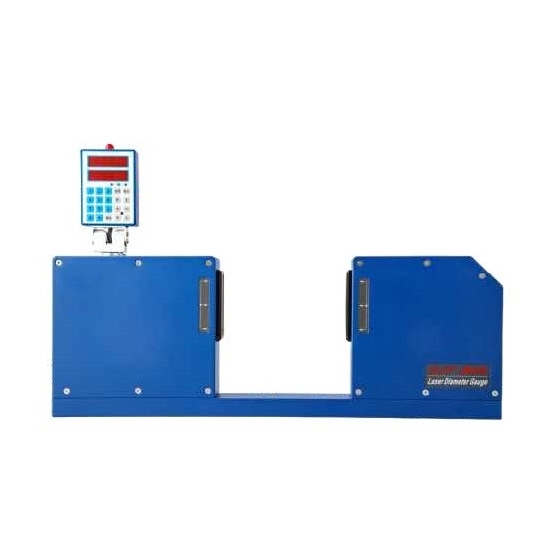

- Laser diameter gauge is a measurement of diameter value, with a multi-angle display of the operation panel.

- This laser diameter measuring equipment adopts fully automatic closed-loop control technology and advanced DSP processing technology.

- The measurement process is not affected by speed and vibration.

- It comes with an over-tolerance alarm function.

- It adopts high-quality stainless steel fasteners, an aluminum die-casting shell, a plastic spraying surface, and good corrosion resistance.

- RS232/485/MODBUS protocol communication interface.

Specification

| Model | RDDLZ-CJY-60A |

| Measuring Range | 1-60mm |

| Measuring Accuracy | ±5μm±0.008%Dz mm (Dz is the actual diameter of the measured object) |

| Resolution Ratio | 0.001mm |

| Scanning Speed | 1400 Times Scanning Cycle/Second |

| Power Supply | 100~240V AC, 1A |

| Working Frequency | 50/60Hz |

| Display Method | Two-Row 5-Digit Pipe Display |

| Light Source | Second Generation Visible Laser, Wavelength 650nm |

| Working Principle | Non-Contact Laser Scanning |

| Data Collection and Analysis | Support (Need to connect to an external computer and install related software) |

| Out-of-Tolerance Alarm Function | Dual relay contact output, upper and lower deviation signals are output separately (External sound and light alarm 24V DC and below) |

| Working Temperature | 0~45℃ |

| Relative Humidity | ≤85%RH (No Condensation Water) |

| Other Environmental Requirements | The air does not contain corrosive gases, serious volatile oils, water vapor and dust. |

| Power Consumption | ≤15W (with Adapter + 40W) |

| Communication Mode | Communication Method: Use RS485 interface, MODBUS RTU protocol/TCP protocol (Ethernet) to communicate with other devices |

| Protection Grade | IP65 |

| Dimension | 575*64*354mm (L*W*H) |

| Weight | 7.1kg |

Dimension (Unit: mm)

Tips: When using a laser diameter gauge, is it necessary to perform special treatment on the object being measured?

When using a laser diameter measuring gauge, it is usually not necessary to perform special treatment on the object being measured. The laser diameter measuring instrument uses the high precision and non-contact characteristics of the laser to directly measure the diameter of the object. However, to ensure the accuracy and stability of the measurement, there are several points to note:

- Surface cleanliness: The surface of the object being measured should be as clean as possible to avoid dust, oil, etc. that affect the laser reflection.

- Ambient light: Avoid direct strong light or too dark environment to avoid interfering with laser measurement.

- Object position: Make sure that the object being measured is within the effective measurement range of the measuring instrument and that the measurement position remains stable.

- Material reflectivity: For highly reflective or transparent materials, it may be necessary to adjust the laser power or use reflective stickers to improve measurement accuracy.