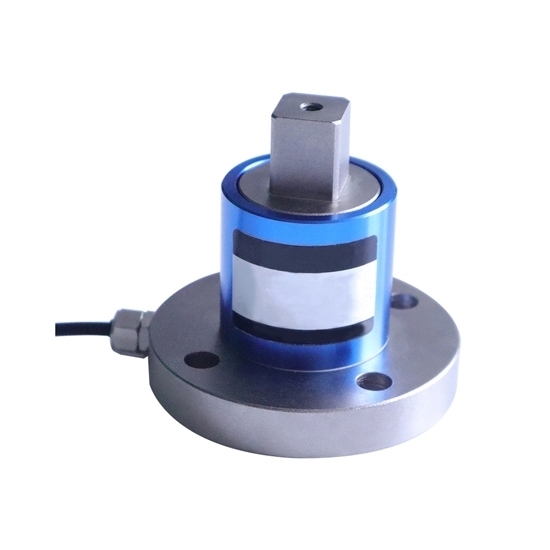

Reaction Torque Sensor, Flange To Square Drive, 2/10/30/50/100/200 Nm

from

$134.92

Ex Tax: $134.92

- Stock: In Stock

- Model: RDDLZ-TQS-S03

- Weight: 1.00

- SKU: RDDLZ-TQS-S03

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Torque sensors have capacity range from 2 Nm, 5 Nm, 10 Nm, 20 Nm, 30 Nm, 50 Nm, 100 Nm to 2000Nm. Torque sensor capacity can be customized according to customer requirements. After purchasing one RDDLZ torque sensor, you can buy a special digital panel meter to obtain readings directly, or buy a matched transmitter to output standard signal to PLC, DCS and other systems. Customized output signal is 0~5V, 0~10V, 0~±10V, or 4-20mA.

Specification

| Model | RDDLZ-DYJN-103 |

| Shipping Weight | 1.5kg |

| Capacity Range * | 0-2000 Nm (Contact us for your specific capacity) |

| Sensitivity | 1.0-2.0mV/V |

| With Transmitter | RDDLZ-LCTR-OAR |

| Accuracy | 0.3%FS |

| Zero Balance | ±2%FS |

| Non-linearity | 0.2%FS |

| Hysteresis | 0.05%FS |

| Repeatability | 0.05%FS |

| Creep | 0.05%FS/30min |

| Temperature Drift on Zero | <0.05%F.S/10℃ |

| Temperature Effect on output | <0.05%F.S/10℃ |

| Operating Temperature | -20℃~+80℃ |

| Humidity | 0~90%RH |

| Impedance | 350Ω |

| Insulation Resistance | ≥5000MΩ/100VDC |

| Stability | 0.3%FS/year |

| Safety Overload | 120%F.S |

| Ultimate Overload | 150%F.S |

| Excitation Voltage | DC 5-15V |

| Material | Alloy steel |

| Protection Class | IP65 |

| Cable Length | 3m (Φ3mm) |

| Wiring | EXC+: Red, EXC-: Black, SIG+: Green, SIG-: White |

Reaction Torque Sensor Flange to Square Drive Dimension (unit:mm)

Dimension (mm)

| Capacity | A | H1 | H2 | H3 | Φ1 | Φ2 | Φ3 | Φ |

| 2-200 Nm | 12.5 | 55 | 30 | 15 | 59 | 32 | 45 | 6.5 |

| 300-800 Nm | 25.4 | 75 | 40 | 24 | 68 | 40 | 55 | 8.5 |

| 1000-2000 Nm | 25.4 | 85 | 44 | 24 | 98 | 56 | 80 | 13 |

Force Diagram

Wiring Diagram

Tips: Application of torque sensor in Lift Bridge

- Vertical Lift Bridge

The mechanical rework and painting of the vertical lift bridge will probably change the weight of the mobile span. At this moment, in order to ensure the normal and safe operation in the later period, checking the balance between the span and weight is quite essential. How to check the entire balance of the balance weight cable system? A big cable can be used to connect the span with the counter weight through the pulley driven by the motor on each corner of the bridge. The torque is measured on the four drive shafts at the same time, so as to confirm if the four corners have any imbalance. Through the torque sensor and the remote telemeter connecting to each drive shaft, the torque data will be recorded in lifting and lowering the span. Through comparing the lifting torque and lowering torque, and correcting the friction, it can be proved that the movable span is slightly heavier than the combined counter weight (required condition), and all four corners are in the acceptable balance scope. - Two-leaf open bridge

The Park Street Bridge in Alameda County, California is a four-lane, two-leaf open bridge spanning 372 feet. It is located between City of Alameda and Oakland.

When the rework structure changes the weight of the original elevator, the engineers of Alameda County need to determine the appropriate counterweight to prevent the elevator drive motor from overloading. By measuring the torque on the main pinion shaft used to lift the bridge, the drive load can be easily determined and optimized by adjusting the counterweight on each span. The strain gauge of the torque sensor is connected with the pinion drive shaft and two wireless torque telemetry systems are used to simultaneously transmit strain gauge signals from the two pinions as the shaft rotates.

Alameda County has many movable bridges. Because of repair or other mechanical changes, they are occasionally in need of adjustment. Using the wireless torque sensor remote equipment can quickly and accurately conduct torque and balance measurement, eliminate the suspected and potential problems of motor driver overload.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.