- Stock: In Stock

- Model: RDDLZ-STEP-34L400

- Weight: 1.00

- SKU: RDDLZ-STEP-34L400

Available Options

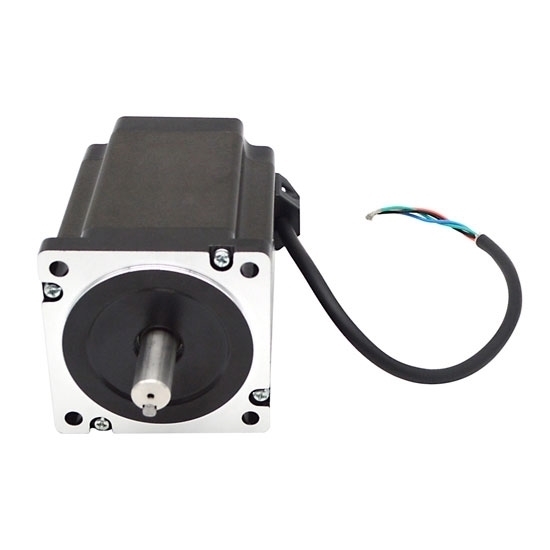

High precision Nema 34 closed loop stepper motor with high holding torque of 8.5 N·m is suitable for the biggest projects, such as CNC application, robotic, 3D technology and so on. The bipolar stepper motor is 1.8 degrees per step with 14mm or 12.7mm shaft size and encoder performed well in various applications.

Physical Specification

- Model Number: RDDLZ-FY86EL400A

- Matched the Driver Model: RDDLZ-FYDM808T

- Flanged Size: 86 x 86mm (Nema 34)

- Motor Length: 118mm

- Shaft Diameter: 14mm/ 12.7mm

- Number of Leads: 4 wire

- Weight: 3.8kg

Electrical Specification

- Motor Type: Bipolar Stepper

- Step Angle: 1.8°

- Rated Current: 4A

- Holding Torque: 8.5 N·m (850 N·cm, 1204 Oz.in)

- Phase Resistance: 0.97Ω

- Phase Inductance: 5.5mH

- Rotor Inertia: 4100g·cm2

Dimensions (Unit: mm)

L=118mm

Wiring Diagram

Speed-Torque Curve Diagram

Details

Tips: Application of stepper motor in automobile test

The detection of many automobile brake components requires a stepper motor in the test system.

Since the angular displacement of the stepper motor is strictly proportional to the input pulse, there is no accumulated error during its movement and the follow ability is good. Therefore, the stepper motor is a better performing component in the automotive brake component test system. The system hardware consists of displacement sensor, force sensor, motor, and the control core adopts industrial computer and data acquisition card.

The hybrid stepper motor drives the ball screw through the coupling to form a force adding device. The force sensor is installed at the front end of the screw rod to measure the output torque of the motor and the "input force of the test piece". The industrial computer controls the start, advance, and back, stop, and control the speed of forward and backward according to the test program.