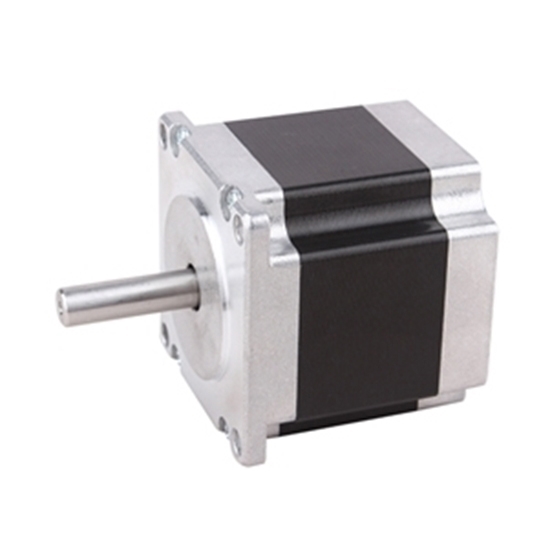

Nema 23 Bipolar Stepper Motor, 3A, 1.8 Degree, 4 Wires

from

$63.31

Ex Tax: $63.31

- Stock: In Stock

- Model: RDDLZ-STEP-2462303

- Weight: 1.00

- SKU: RDDLZ-STEP-2462303

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Nema 23 bipolar Stepper motor, 3A phase current, 1.2Nm in 56mm, 1.8 degree, 2phase 4 wires, manufacturer direct sale.

Specification

| Electrical Specification | Model | RDDLZ57HS56-3004 |

| Matched Driver Model | RDDLZDSP57(Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 1.2Nm | |

| Rated Current/phase | 3A | |

| Phase Resistance | 0.95Ω | |

| Inductance | 2.8mH | |

| Rotor Inertia | 300g-cm2 | |

| Physical Specification | Frame Size | 57 x 57mm |

| Length | 56mm | |

| Shaft Diameter | Φ8mm | |

| Shaft Length | 19mm | |

| Motor Leads | 4 | |

| Weight | 0.7kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -20℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.02Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

Dimensions: (Unit=mm)

L Max=56mm, Shaft Length=L1-1.6mm, L1(Common)=20.6mm

Wiring Diagram

Tips: What should be checked before powering on the stepper motor?

- Check whether the power is proper (in case of overvoltage, the drive module may be damaged); the positive and negative polarity of DC input should not be wrong. Whether the motor type or current setting on the drive controller is proper (not too large at the very beginning).

- Control signal line is connected firmly and it’s better to give considerations into the problem about shielding (like using twisted-pair) at the industrial field.

- At the very beginning, do not directly connect all necessary lines but the most basic system, and then connect one by one after the motor rotates in good state.

- Be clear about earthing methods, or don’t connect it.

- Closely observe the state of motor within 30min after the motor rotates, like whether it rotates normally, as well as sound and temperature rise. If discovering the problem, please stop it and make adjustment.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.