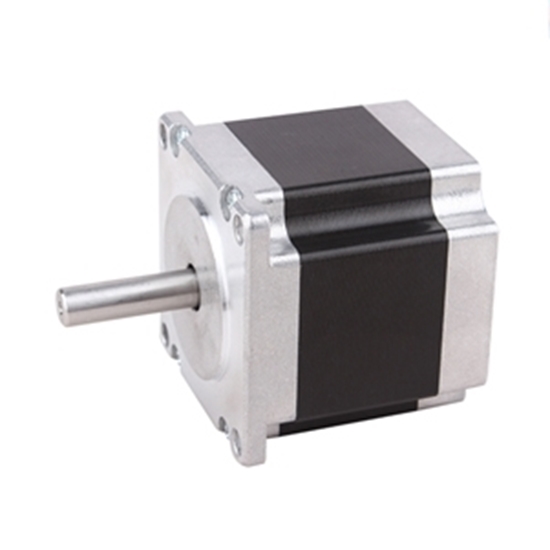

Nema 23 Bipolar Stepper Motor, 2A, 1.8 Degree, 4 Wires

from

$63.31

Ex Tax: $63.31

- Stock: In Stock

- Model: RDDLZ-STEP-2462302

- Weight: 1.00

- SKU: RDDLZ-STEP-2462302

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Nema 23 bipolar Stepper motor, 0.5Nm in 41mm, 1.8 degree, 2 phase 4 wires, manufacturer direct sale.

Specification

| Electrical Specification | Model | RDDLZ57HS41-2004 |

| Matched Driver Model | RDDLZDSP57(Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 0.5Nm | |

| Rated Current/phase | 2A | |

| Phase Resistance | 1Ω | |

| Inductance | 2.2mH | |

| Rotor Inertia | 120g-cm2 | |

| Physical Specification | Frame Size | 57 x 57mm |

| Length | 41mm | |

| Shaft Diameter | Φ8mm | |

| Shaft Length | 19mm | |

| Motor Leads | 4 | |

| Weight | 0.45kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -20℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.02Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

Dimensions: (Unit=mm)

L Max=41mm, Shaft Length=L1-1.6mm, L1(Common)=20.6mm

Wiring Diagram

Tips: Three factors should be paid attention to in selection of the stepper motor

- Stepping angle

it is necessary to select the stepping angle of stepper motor according to the requirements of load precision. The least resolution ratio of the load is generally converted to the motor shaft, pay attention to the angle for each resolution ratio and the stepping angle of stepper motor should be equal to or smaller than the angle. - Static torque

Select the static torque according to the load of stepper motor while load can be divided into inertia and friction load. When directly starting the stepper motor (generally from the low to high velocity), the considerations into the two kinds of load are given. When starting the motor at acceleration, give considerations into the inertia load; when the motor rotates at constant velocity, only give considerations into the friction load. Generally, the static torque shall be within 2-3 times of the friction load. - Current

As for the stepper motors with the same static torque, there is great difference in their motion characteristics due to the difference in current parameters. The current of stepper motor can be judged according to the torque frequency characteristic curve diagram.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.