- Stock: In Stock

- Model: RDDLZ-STEP-391712

- Weight: 1.00

- SKU: RDDLZ-STEP-391712

Available Options

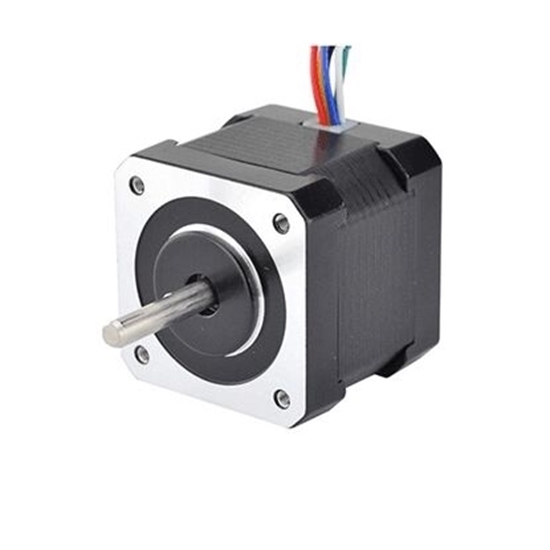

2 phase, 6-wire Nema 17 stepper motor with 1.8 degree step angle, each phase draws current 1.2A at 4V, allowing for a holding torque of 36oz-in.

Specifications

| Electrical Specification | Model | RDDLZ39-1206A |

| Matched the Driver Model | RDDLZDSP42 (Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 2.59kg-cm(36oz-in) | |

| Voltage | 4V | |

| Rated Current/phase | 1.2A | |

| Phase Resistance | 3.3Ω | |

| Inductance | 4mH | |

| Rotor Inertia | 54g-cm2 | |

| Physical Specification | Frame Size | 42 x 42mm |

| Length | 39mm | |

| Shaft Diameter | Φ5mm | |

| Shaft Length | 22mm | |

| Motor Leads | 6 | |

| Weight | 0.28kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 1Min. 500VAC·5mA | |

| Shaft Radial Play | 0.06Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

Nema 17 Stepper Motor Dimension (Unit=mm)

L1=24mm, Lmax=39mm

Nema 17 Stepper Motor Wiring Diagram

Tips: Low frequency characteristic of servo motor and stepper motor

Stepper motor at low speed is easy to appear low frequency vibration phenomenon. Vibration frequency is associated with load and drive performance, it is generally believed half frequency vibration frequency for the motor no-load takeoff. This determined by the working principle of stepper motor in low frequency vibration phenomenon is very bad for the normal operation of the machine. When the stepper motor work in low speed, general damping technology should be adopted to overcome the low frequency vibration phenomenon, such as add damper on motor, or drive the segmentation technology, etc..

Ac servo motor running smoothly, even in the low speed also won't appear when the vibration phenomenon. Ac servo system has a resonance suppression function, can cover the mechanical rigidity, and internal system has the function of frequency resolution (FFT), can detect the mechanical resonance point, is advantageous for the system adjustment.