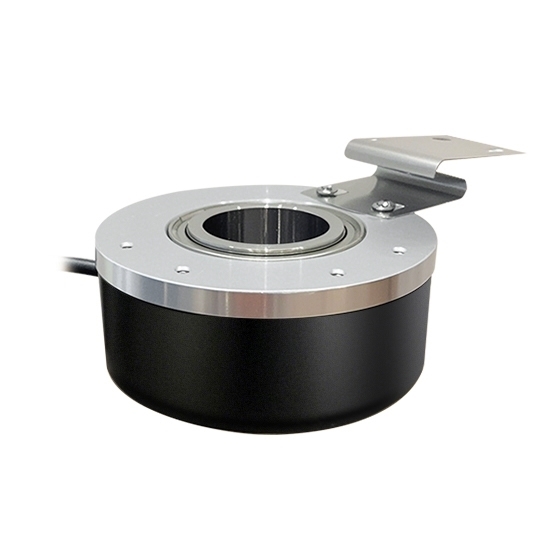

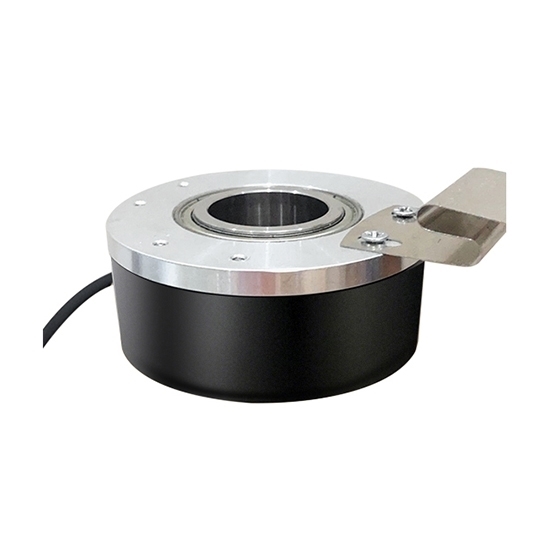

Incremental Rotary Encoder, Hollow Shaft, 2048 Ppr

from

$237.46

Ex Tax: $237.46

- Stock: In Stock

- Model: RDDLZ-IRE-2048PH

- Weight: 1.00

- SKU: RDDLZ-IRE-2048PH

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Incremental rotary encoders with 2048 ppr can be used for robots, workbenches, injection molding machines, electronic equipment, printing and packaging machinery, non-standard equipment and CNC machine, a variety of office automation systems, industrial automation control and measurement fields.

Specification

| Basics | Model | RDDLZ-K8020G-2048BM | |||||||||||||||||||

| Weight | 100g | ||||||||||||||||||||

| Wiring | Color | Red | Black | Green | White | Yellow | Brown | Gray | Orange | ||||||||||||

| Signal | Vcc | GND | A | B | Z | A- | B- | Z- | |||||||||||||

| Mechanical properties | Maximum shaft speed (r/min) | 5000 | |||||||||||||||||||

| Starting torque | <0.03Nm (25℃) | ||||||||||||||||||||

| Maximum shaft load | Radial load: 20N, axial load: 10N | ||||||||||||||||||||

| Shock resistance | 50G/11ms | ||||||||||||||||||||

| Anti-vibration | 10G (10~2000Hz) | ||||||||||||||||||||

| Rotational inertia | 4X10-8kgm2 | ||||||||||||||||||||

| Operating temperature | -30~+85℃ (-22~+185℉) | ||||||||||||||||||||

| Storage temperature | -35~+95℃ (-31~+203℉) | ||||||||||||||||||||

| Protection Level | IP51 | ||||||||||||||||||||

| Electrical characteristics | Output circuit | Open-collector output | Voltage output | Push-pull output | Line driver output | ||||||||||||||||

| Supply voltage Vcc | DC 5V±0.2 | DC 5~24V | DC 5V±0.2 | DC 5~24V | DC 5V±0.2 | DC 5~24V | DC5V±0.2 | DC 5~24V | |||||||||||||

| Current consumption | ≤60mA | ≤60mA | ≤60mA | ≤100mA | |||||||||||||||||

| Output high level | ≥3.5V | ≥Vcc-2.5V | - | - | ≥2.5V | ≥Vcc-2.5V | |||||||||||||||

| Output low level | ≤0.5V | ≤0.5V | - | - | ≤0.5V | ≤1.0V | |||||||||||||||

| Rise time Tr | ≤500ns | ≤1500ns | - | - | ≤200ns | ≤500ns | |||||||||||||||

| Fall time Tf | ≤100ns | ≤300ns | - | - | ≤200ns | ≤200ns | |||||||||||||||

| Maximum frequency response | 0~150kHz | 0~150kHz | 0~150kHz | 0~150kHz | 0~150kHz | 0~150kHz | |||||||||||||||

Model selection

| Shaft type | Diameter of shell | Diameter of shaft | Connection type | Cable length * | Resolution | Production identifier | Z signal | Z signal wavelength | Output mode * | Voltage * |

| K: Hollow shaft | 80: 80mm | 20: 20mm | G: Cable edge output | 1: 1m 2: 2m 3: 3m 4: 4m | 2048: 2048 ppr | B | M: Output 1 if receiving Z signal | Default: 1T | C: Open-collector NPN CP: Open-collector PNP T: Voltage ouput NPN+R P: Push-pull output NPN+PNP L: Line driver 26LS31 K: Line driver 7272 | 5: +5VDC 830: +8~30VDC |

Note: * denotes optional parameters, you can select parameters in drop-down lists to finish your order. Some customizable parameters can't be selected from the lists directly, please contact customer service staff for further communication.

Features

- The encoder adopts a special ASIC chip inside, which is stable and reliable in signal processing and ensures accurate output pulse.

- The overall structure is durable, long life, suitable for long time high frequency operation of industrial occasions.

- Incremental encoder has excellent anti-interference performance, can work stably in complex electromagnetic environment.

- Compact and lightweight, suitable for automation equipment with limited installation space.

- Modular design, easy installation, fast and efficient commissioning.

Dimension (unit: mm)

Application

Tips: How to determine the encoder zero position

- Rotate the encoder shaft to correspond zero positon when installing the encoder.

- It is similar to the above method, but rotate the encoder shell and find zero position.

- Power on and move the installation machine tocorrespond zero positon.

- Offset calculation, it is not necessary to find zero for the machinery and encoder, according to the deviation of the encoder readings and the actual position of the calculation, get the offset, after the encoder reading minus the offset. It can be repeated several times to correct the offset.

- Intelligent external zero setting, such as setting zero through the button of the encoder, or the external software.

- The best position-setting method is to preset a non-zero position (leave margins for slip and overshoot), and preset rotation direction and offset calculation. Or set a middle position, the offset is the midpoint value, the setting line and the power is in direct contact, the encoder output is the midpoint position, this trip is +/- half full; within this range of travel, it will not hop zero position every time it goes through regardless of the direction of rotation.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.