- Stock: In Stock

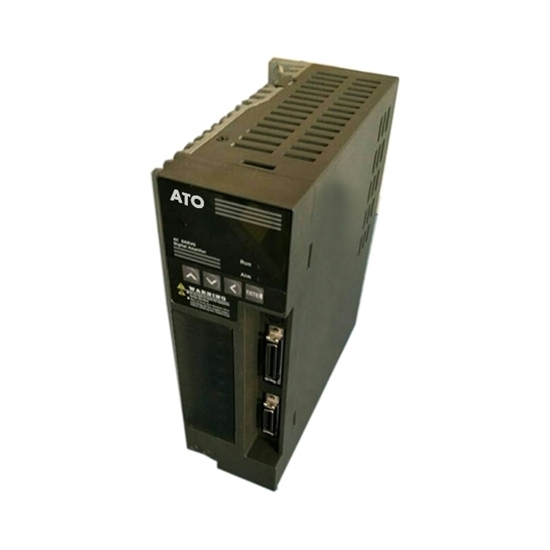

- Model: RDDLZ-MG1000

- Weight: 1.00

- SKU: RDDLZ-MG1000

Available Options

Features

- AC servo drive 220V, 380V for choice. 220V single phase or three phase input, 380V three phase input.

- Support modbus RS485 and RS232 communication protocol.

- Position, speed, and torque control.

- Requires 2500PPR encoder input.

- Capable of updating the information of 1000 I/O.

Specifications

| Model | RDDLZMG-1000 | |

| Matching Servo Motor Model | RDDLZ-SERVO-40S50 (50W servo motor) RDDLZ-SERVO-40S100 (100W servo motor) RDDLZ-SERVO-150S3000 (3 kW servo motor) RDDLZ-SERVO-150S3500 (3.5 kW servo motor) RDDLZ-SERVO-180S3700 (3.7 kW servo motor) RDDLZ-SERVO-150S3800 (3.8 kW servo motor) RDDLZ-SERVO-180S4500 (4.5 kW servo motor) RDDLZ-SERVO-150S5500 (5.5 kW servo motor) RDDLZ-SERVO-180S7500 (7.5 kW servo motor) | |

| Current of IPM module | 20A/30A/50A/75A | |

| Control power supply and main circuit power supply |

Note: Servo drive can be used for 1-phase, but the performance will better if it is supplied via 3-phase) | |

| Environment | Temperature | Working temperature: 0 - 55℃ Storage temperature: -40℃ - 80℃ |

| Humidity | No more than 90% ( without condensation) | |

| Air index | No dust (conductive media such as metal powder, etc.) in the electric cabinet | |

| Control Mode |

| |

| External I/O |

| |

| Encoder Feedback | 10000p/r (standard); frequency division permissible (options) | |

| Communication Mode |

| |

| Load Inertia | Less than 5 times the inertia of the motor | |

| Monitoring Function | Speed, current position, command pulse accumulation, position deviation, motor current, operation status, input and output terminals, and Z pulse signal, etc. | |

| Protection Function | Overvoltage, overcurrent, over-speed, and incorrect feedback, etc. | |

| Alarm Function | Alarms (LED flashing; red lamp on) are often given off when the servo operates abnormally. | |

| Gain Adjustment | Gain adjustment can be carried out to match motor performance when the motor operates or stops. | |

| Adaptive Motor | RDDLZ AC servo motors | |

Tips: How does a servo drive work?

The servo driver adopts digital signal processor (DSP) as the control core, an realize the complex control algorithm, digitization, networking and intelligentialization. The power device generally adopts intelligent power module (IPM) as the driving circuit of the core design. IPM integrated drive circuit with over-voltage and over-current, overheating, undervoltage fault detection and protection circuit. The soft start circuit is also added in the major loop, so as to reduce the impact on thedrive in the start-up process.

First, the power drive unit is rectified by the three-phase full bridge rectifier circuit to input the three-phase electric or municipal power, and the corresponding DC power is obtained. The three-phase power or electric supply after rectifying can drive the AC servo motor through three-phase sine PWM voltage source inverter frequency conversion. The whole process of the power drive unit can be simply described as the process of AC-DC-AC. The main topology of the rectifier unit (AC-DC) is the three-phase full bridge uncontrolled rectifier circuit.