- Stock: In Stock

- Model: RDDLZ-AS15400

- Weight: 1.00

- SKU: RDDLZ-AS15400

Available Options

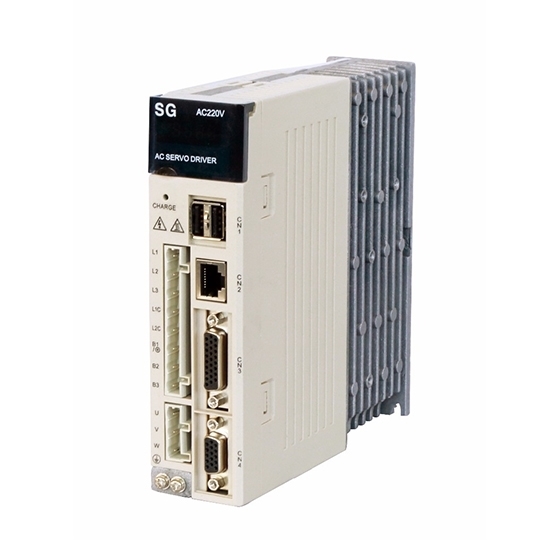

AC Servo Drive for 200W-400W Servo Motor offers superior high speed performance, high functionality and closed loop control. Application fields including CNC machining equipment, food processing machine, material conveying equipment, medical apparatus and instruments, textile machinery and so on.

Servo Drive Specification

| Model | RDDLZ-SG-AS15400 (Click it to see more specifications) | |||||

| Matching Servo Motor Model | RDDLZ-SERVO-60S200 (200W servo motor) RDDLZ-SERVO-60S400 (400W servo motor) | |||||

| Manual | Servo Driver product Manual Servo Driver User Manual | |||||

| Output Power | 200W-400W | |||||

| Voltage | Single/three phase 220V AC | |||||

| Input Signal Type* | Pulse + analog (±10V) signal or pulse signal (Optional) | |||||

| Current | 15A | |||||

| Control Mode | Position control, Speed control, JOG operation | |||||

| Encoder Feedback | 2500 lines incremental encoder | |||||

| 17/23 bit absolute encoder | ||||||

| Structure | Base-mounted type | |||||

| Weight | 1.5 Kg | |||||

| Application | for 200W-400W AC servo motor | |||||

| Operate Temperature | 0℃~+50℃ | |||||

| Humidity | <90% (no frost) | |||||

Note: Our AC Servo Drive will come with a RS485 control software, so you can only monitor the motor parameters through 485 communication, but you cannot use it to control the motor.

Servo Drive Terminal Details

| NO. | Name | Description | |||||||

| 1 | Front Cover | -- | |||||||

| 2 | Nameplate | Indicates the SERVOPACK model and rating. | |||||||

| 3 | Input Voltage | -- | |||||||

| 4 | Charge | Lights up when the main circuit power is turned on. Note: Even if you turn OFF the main circuit power supply,this indicator will be lighting as long as the internal capacitor remains charged. Do not touch the main circuit or motor terminals while this indicator is lighting. Doing so may result in electric shocks. | |||||||

| 5 | Main Circuit Terminals | The terminals depend on the main circuit power supply input specifications of the SERVOPACK. | |||||||

| 6 | Servo Motor Terminals (U,V,W) | The connection terminals for the servo motor main circuit cable (power line). | |||||||

| 7 | Ground Terminal | The ground terminals to prevent electric shock. Always connect this terminal. | |||||||

| 8 | 485 Communication Connector (CN1,CN2) | -- | |||||||

| 9 | I/O Signal Connector (CN3) | Connect to reference input signals and sequence I/O signals. | |||||||

| 10 | Encoder Connector (CN4) | Rotary servo motor: Connect to the encoder in the servo motor. Linear servo motor: Connect to a serial converter unit or linear encoder. | |||||||

| 11 | Panel Display | Used to display SERVOPACK status, alarm numbers, and parameters. | |||||||

| 12 | Panel Operation keys | Used to set parameters. | |||||||

| 13 | Panel Operator | -- | |||||||

Servo Drive Dimension

Tips: Installation and wiring

Installed in electrical control cabinet

Due to the heating of electric devices in electrical control cabinet and thermal environment situation in cabinet, the temperature around servo driver will continue to rise. So considering about the configuration in the control cabinet and cooling of driver, it should be ensured that air temperature is under 50 degrees and relative humidity is under 90 percent. Long-term safe working temperature should be under 45 degrees.

Vibratory equipment around

Whichever anti-vibration measure could be adopted to guarantee servo driver unaffected, and vibration to be under 0.5G.

Jamming devices around

It strongly interferences the power wire and control wire of servo device when some jamming devices around the driver, which leads to wrong action of servo driver. A noise filter and any anti–interference method could be applied to assure driver working normally. Do pay attention to the increasing of leakage current after a noise filter added. To avoid this problem, an isolation transformer could be used.

Take special notice: the control signal wire of servo driver is very susceptible to interference, therefor wiring and shielding protection should be reasonable.