- Stock: In Stock

- Model: RDDLZ-TQS-NJY40

- Weight: 1.00

- SKU: RDDLZ-TQS-NJY40

Available Options

Unlike dynamic torque transducer, which is used for measuring torque in rotating systems, static torque sensor focus on stationary applications. This sensor is employed in scenarios such as torque wrench calibration, bolt tightening verification, and material testing.

Specification

| Model | RDDLZ-LZ-NJY40 |

| Sensitivity | 1.5-2.0 mV/V |

| Material | Stainless steel |

| Non-Linearity | ≤±0.5% F. S |

| Repeatabilit | ≤±0.5% F. S |

| Creep | ≤±0.5% F. S/30 min |

| Zero Temperature Drift | ≤±0.05% F. S/10°C |

| Sensitivity Temperature Drift | ≤±0.05% F. S/10°C |

| Working Temperature | -20°C~60°C |

| Input Impedance | 380±30Ω/730±30Ω |

| Output Impedance | 350±2Ω/700±3Ω |

| Insulation Resistance | ≥5000MΩ/100VDC |

| Safety Overload | 120% F. S |

| Bridge Voltage | 5-12VDC |

Feature

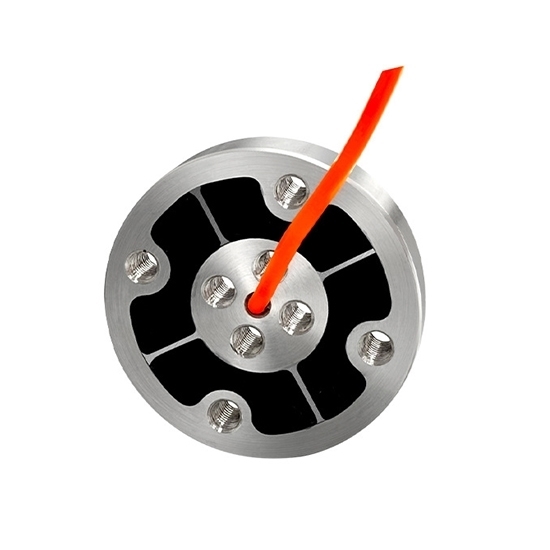

- Compact size, stainless steel material, with high precision and good stability.

- Strong anti-interference capability and easy installation.

- Low Maintenance. Static torque sensors generally have fewer moving parts compared to dynamic torque sensors.

- Durability. These sensors are designed to withstand harsh conditions, making them durable in demanding environments.

Dimension: (Unit: mm)

Detail

- Outlet Position: The cable leads out from the center of the sensor, which is convenient for wiring and installation.

- Selected High Quality Steel: The static torque transducer is made of special material, which ensures quality and peace of mind.

- Thread: Standard threaded interface ensures stable connection and high precision measurement.

- Multi-scenario Application: Suitable for disk connections, drilling rigs and industrial automation in a variety of static, non-continuous rotating torque value measurement fields.

Wiring Method

Tips: Are There Any Calibration Requirements For Static Torque Sensor?

Yes, calibration is a crucial aspect of ensuring the accuracy and reliability of static torque sensors. Calibration requirements for torque sensors involve periodic adjustments to maintain precision and consistency in torque measurements. The calibration process typically involves comparing the sensor's output to a reference standard, identifying any deviations, and making necessary corrections. The frequency of calibration depends on factors such as usage conditions, environmental factors, and industry regulations. Calibration ensures that the sensor provides accurate and consistent readings over time, improving the overall reliability of torque measurements in various applications, including manufacturing, automotive, and aerospace.