- Stock: In Stock

- Model: RDDLZ-SFYS-PRS2

- Weight: 1.00

- SKU: RDDLZ-SFYS-PRS2

Available Options

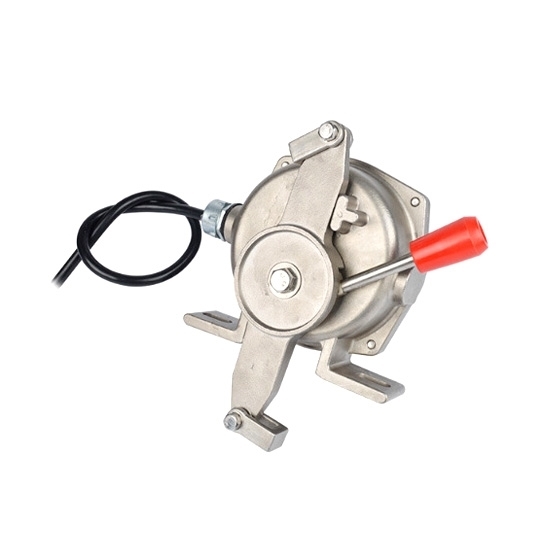

Two-way pull rope switch has optional contactors 1NO+1NC or 2NO+2NC, contact capacity 6A/380VAC, 5A/380VAC, or 10A/500VAC, return mode automatically/manually.

Application: Conventional belt conveyor, shuttle conveyor, feeder conveyor, bucket elevator, packaging production line, stacker-reclaimer system, crane, excavator, ship loading and unloading system, horizontal feeder, etc.

Specification:

| Model | RDDLZ-SFYS-LS-I | RDDLZ-SFYS-LS-II | RDDLZ-SFYS-EPLS-I | RDDLZ-SFYS-EPLS-II | RDDLZ-SFYS-LSB-I | RDDLZ-SFYS-LSB-II | RDDLZ-SFYS-HFKLT2-II | RDDLZ-SFYS-JHLX-III |

| Shipping weight | 4kg | 4.5kg | 4kg | 4.5kg | 3.5kg | 3.5kg | 5.5kg | 4kg |

| Direction | 2-way | 2-way | 2-way | 2-way | 2-way | 2-way | 2-way | 2-way |

| Contact type * | 1NO+1NC | 1NO+1NC | 1NO+1NC | 1NO+1NC | 1NO+1NC, 2NO+2NC | 1NO+1NC, 2NO+2NC | 1NO+1NC, 2NO+2NC | Single-pole double-throw switch |

| Contact capacity * | 6A/380VAC | 6A/380VAC | 6A/380VAC | 6A/380VAC | 5A/380VAC | 5A/380VAC | 5A/380VAC | 10A/500VAC |

| Return mode * | Automatically return | Manually return (with handle) | Automatically return | Manually return (with handle) | Automatically return | Manually return (with reset button) | Manually return (with handle) | Manually return (with reset button) |

| Shell material * | Cast aluminum | Cast aluminum | Cast aluminum (explosion-proof) | Cast aluminum (explosion-proof) | Cast aluminum | Cast aluminum | Stainless steel | Cast aluminum |

| Action angle | 30° | 30° | 30° | 30° | 30° | 30° | 30° | 30° |

| Limit angle | 60° | 60° | 60° | 60° | 60° | 60° | 75° | 60° |

| Operating force | 10kg | 10kg | 10kg | 10kg | 3kg | 10kg | 10kg | 3~8kg |

| Operation way | Pull the rope | Pull the rope | Pull the rope | Pull the rope | Pull the rope | Pull the rope | Pull the rope | Pull the rope |

| Max. distance between two switches | 25m | 25m | 25m | 25m | 40m | 40m | 30m | 30m |

| Spacing between lifting rings | 3m | 3m | 3m | 3m | 10m | 10m | 5m | 10m |

| Working temperature | -30~+50℃ (-22~+122℉) | -30~+50℃ (-22~+122℉) | -30~+50℃ (-22~+122℉) | -30~+50℃ (-22~+122℉) | -30~+50℃ (-22~+122℉) | -30~+50℃ (-22~+122℉) | -30~+75℃ (-22~+167℉) | -15~+65℃ (+5~+149℉) |

| Working humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤85% | ≤85% | ≤85% | ≤90% |

| Working life | ≥1million times | ≥1million times | ≥1million times | ≥1million times | ≥1million times | ≥1million times | ≥1million times | ≥1million times |

| Protection class | IP65 | IP65 | IP65 | IP65 | IP65 | IP65 | IP65 | NEMA4 |

| Cable length | 1.5m | 1.5m | 1.5m | 1.5m | 1.5m | 1.5m | 1.5m | 1.5m |

| Indicator | Yes | Yes | No | No | No | No | No | No |

| Accessories * | a) wirerope covered with plastics, b) mounting bracket, c) lifting ring, d) wire buckle, e) waterproof junction box | |||||||

Tips: How to install a pull rope switch?

The pull rope switch is installed on the rack of both sides of the belt conveyor, and the switches are connected along the two sides of the conveyor with a wire rope. When an emergency occurs on the conveyor belt equipment, pull anywhere of the rope on the site, the wire rope drives the driving arm to rotate, the torque spring is driven by the transmission shaft to move the precision cam, and the micro switch is driven to cut off the power of control line, so that the belt conveyor stops.

So the cable pull switch should be installed in the place with safety maintenance access on both sides of the conveyor, and the installation position should ensure that the maintenance personnel can easily operate in emergency situations.

Installation method:

- The switch is evenly mounted on the fixed bracket of the rack.

- Tie the steel wire rope to the pull rings at the upper and lower ends of the pull rope switch. The wire rope on each side has a maximum rope length, and it should be shorter when there is a slope.

- The pull rope pressure force should be appropriate to ensure the switch can be reset reliable.

- In order to reduce the influence of the weight of the steel wire rope on starting switch, pull rings should be installed along the parallel direction of the tape to support the steel wire rope.