- Stock: In Stock

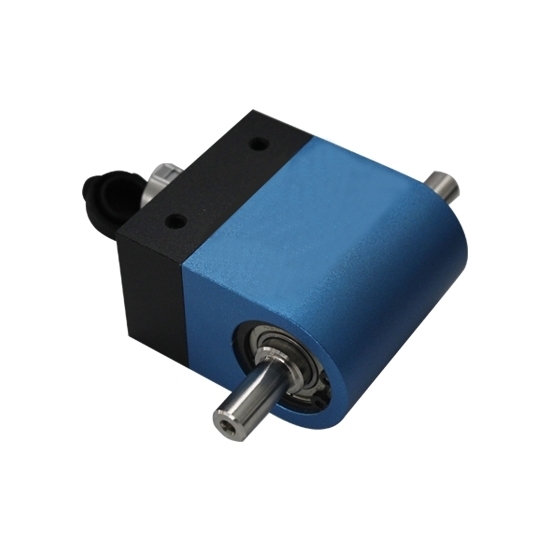

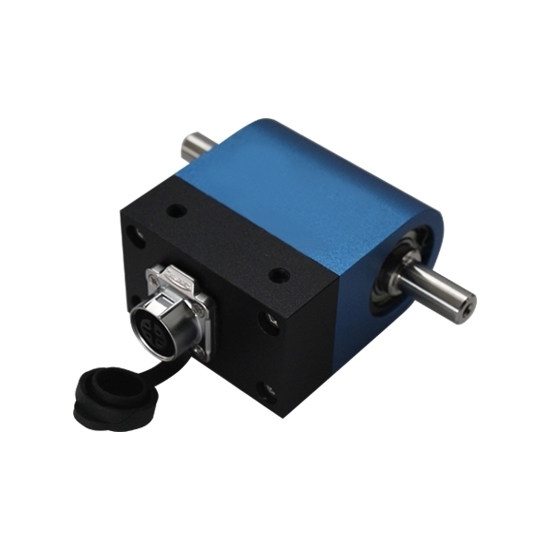

- Model: RDDLZ-TQS-D02

- Weight: 1.00

- SKU: RDDLZ-TQS-D02

Available Options

Rotary torque sensors have capacity range from 0.1 Nm, 0.2 Nm, 0.3 Nm, 0.5 Nm, 1 Nm, 2 Nm, 3 Nm to 5 Nm. Torque sensor capacity can be customized according to customer requirements.

After purchasing one RDDLZ rotary torque sensor, you can buy a special digital panel meter to output standard signal to PLC, DCS and other systems. Customized output signal is 4-20mA, 0-10V, -5V~+5V, RS485 and RS232.

Specification

| Model | RDDLZ-DYN-205 |

| Shipping Weight | 1.5kg |

| Capacity Range * | 0-1 Nm ~ 0-5 Nm |

| Output Signal * | DC 0-20mV, or equip display controller RDDLZ-DPM-DY056 for output signal DC 4-20mA, 0-10V, -5V~+5V, RS485, RS232 |

| Sensitivity | 1.0-1.5mV/V |

| Zero Balance | ±2%FS |

| Non-linearity | 0.1%FS |

| Hysteresis | 0.03%FS |

| Repeatability | 0.03%FS |

| Creep | 0.03%FS/30min |

| Temperature Drift on Zero | <0.1%F.S/10℃ |

| Temperature Effect on Output | <0.03%F.S/10℃ |

| Operating Temperature | -10℃~+60℃ |

| Humidity | 0~90%RH |

| Impedance | 350Ω |

| Insulation Resistance | ≥2000MΩ/100VDC |

| Stability | 0.3%FS/year |

| Safety Overload | 150%F.S |

| Ultimate Overload | 200%F.S |

| Excitation Voltage | DC 5-15V |

| Speed Range | 0-3000rpm |

| Material | Stainless steel |

| Protection Class | IP65 |

| Electrical Connection | 5 pin circular connector |

| Cable Length | 3m (Φ5mm) |

| Wiring | EXC+: Red, EXC-: Black, SIG+: Green, SIG-: White |

Mirco Rotary Torque Sensor Dimension (unit: mm)

Details

Mirco Rotary Torque Sensor Installation

Force Diagram

Applications

Tips: What is a micro rotary torque sensor and how does it work?

The micro rotary torque sensor is a high-precision sensor for measuring the torque of rotating parts. It monitors the torsional moment of a shaft in real time through strain gauge or magnetic measurement technology and converts the data into an electrical output.

These sensors are commonly used in precision manufacturing, automotive testing, and robot joint control to ensure efficient operation of power systems.

The following key factors should be considered when selecting the right torque sensor:

- Range: Ensure that the sensor can cover the torque range required for your application.

- Accuracy and Resolution: The higher the accuracy, the more reliable the measurements will be for demanding test environments.

- Mounting Methods: Different models of transducers are suitable for different mounting needs, such as shaft type, flange type, etc.

- Data Ouput Mode: Support analog signal, digital signal or wireless transmission to meet the compatibility requirements of different systems.