- Stock: In Stock

- Model: RDDLZ-IMS-716726

- Weight: 1.00

- SKU: RDDLZ-IMS-716726

Available Options

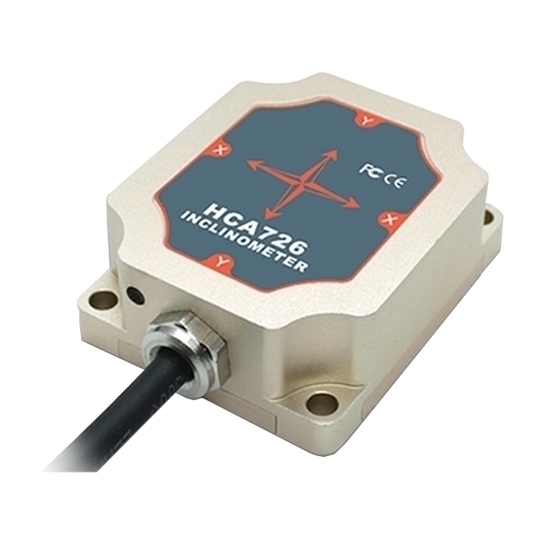

High precision incline sensor for sale, outputs CANopen signal, 1-axis/2-axis, optional maximum measuring angle ±15°~±180°. Low cost tilt switch is suitable for monitoring ancient buildings, dilapidated buildings, etc., as well as large-scale and high-precision industrial measurement sites.

Features

- It is a single/dual-axis inclinometer sensor with small size, using CAN 2.0A/CAN 2.0B serial communication interface, which is dedicated to applications of industrial field control.

- The tilt sensor has a built-in high-precision 24 bit A/D differential converter, which can measure the tilt and pitch angle of the sensor output relative to the horizontal plane through a 5-order filtering algorithm.

- The inclinometer sensor integrates MEMS inclination unit, maximum measurement range is up to ±180°, the full-scale accuracy is 0.01°, which can easily realize dual-axis and single-axis inclination measurement.

- Industrial inclinometer sensor with stable and reliable performance and good scalability.

Technical Specification

| Model | RDDLZ-HCA716/HCA726 | Condition | |||

| Measuring Axis | X/XY (single/dual) | X/XY (single/dual) | X/XY (single/dual) | vertical X (single) | - |

| Measuring Range* | ±15° | ±45° | ±60° | ±180° | - |

| Resolution | 0.001° | 0.001° | 0.003° | 0.005° | - |

| Absolute Accuracy | ±0.008°RMS | ±0.01°RMS | ±0.01°RMS | ±0.01°RMS | @25℃ |

| Long Term Stability | <0.02° | <0.02° | <0.02° | <0.02° | - |

| Zero Temperature Coefficient | ±0.0005°/℃ | ±0.0005°/℃ | ±0.0005°/℃ | ±0.0005°/℃ | -40~85℃ |

| Sensitivity Temperature Coefficient | ≤0.01%/℃ | ≤0.01%/℃ | ≤0.01%/℃ | ≤0.01%/℃ | -40~85℃ |

| Power On Time | 0.5s | 0.5s | 0.5s | - | - |

| Response Time | 0.02s | 0.02s | 0.02s | - | - |

| Response Frequency | >20Hz | ||||

| Output Signal | CAN 2.0A/ CAN 2.0B/ RS485 | ||||

| Electromagnetic Compatibility | According to EN61000 and GBT17626 | ||||

| MTBF | ≥50000 hours/times | ||||

| Insulation Resistance | ≥100MΩ | ||||

| Shockproof | 100g@11ms, 3 Times/Axis (half sinusoid)) | ||||

| Anti-Vibration | 10grms, 10~1000Hz | ||||

| Protection Grade | IP67 | ||||

| High Seismic Performance | >100g | ||||

| Cables | Standard 1m length, wearproof, grease proofing, wide temperature, shielded cables 4*0.4mm2 | ||||

| Dimension | 56*46*20.5mm | ||||

| Weight | 90g (without cable) | ||||

*Note: This Technical data only list ±15°, ±45°, ±60°, ±180° series for reference, other measuring range please refer to the adjacent specifications.

Electrical Specification

| Item | Min | Standard | Max | Condition |

| Power Supply | 9V | 12V, 24V | 36V | Standard |

| Working Current | - | 40mA | - | No-load |

| Working Temperature | -40℃ | - | +85℃ | - |

| Store Temperature | -40℃ | - | +85℃ | - |

CANopen Inclinometer Sensor Electrical Wiring

| Line Color Function | BLACK | WHITE | GREEN | RED |

| GND Power negative | CAN_L | CAN_H | Vcc 9~36V Power positive |

CANopen Inclinometer Sensor Dimensions Diagram (Unit:mm)

Inclinometer Sensor Installation Direction Diagram

The installation must guarantee the inclinometer sensor bottom is parallel to measured face,and reduce the influence of dynamic and acceleration to the tilt sensor. This inclinometer sensor can be installed horizontally or mounted vertically (mounted vertically selection is only applicable to the single axis), for installation please refer to the following scheme.

Tips: How does inclinometer sensor achieve accurate tilt measurement at any angle point?

- The actual tilt of the object cannot be completely tilted according to the strict X and Y orthogonal axes. Factors such as the gap of mechanical parts and the difficulty of determining the actual tilt axis determine that the actual tilt angle is not in the strict X and Y orthogonal directions. When the X axis is tilted, if the horizontal axis error of inclinometer sensor is too large, the tilt angle data in Y direction will change. In fact, Y-axis direction may not really be tilted, and vice versa. Therefore, for the 3~5% horizontal axis error of an ordinary inclinometer sensor, even if the linearity is high, the actual measurement accuracy will be about 3~5% instead of linearity data.

- If the inclinometer sensor does not have allowable input axis misalignment data during the actual installation process, it is difficult to obtain truly accurate tilt data by simple visual inspection. For a tilt sensor that is too large, due to the deviation angle between the sensitive axis and the actual tilt direction of the movement, an additional sine error will be generated on the output of the sensor and superimposed on the output data. As the tilt angle increases, the error gradually increases.

RDDLZ inclinometer sensor solves the above practical problems well, and is a tilt sensor that truly realizes high-precision inclination measurement.