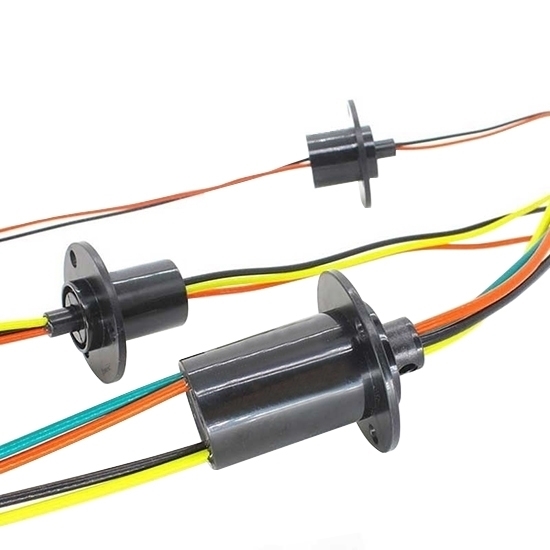

30mm Miniature Electrical Slip Ring, 4-Wire 30A, 2-Wire 50A

from

$99.89

Ex Tax: $99.89

- Stock: In Stock

- Model: RDDLZ-MNTSR-300

- Weight: 1.00

- SKU: RDDLZ-MNTSR-300

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Miniature electrical slip ring core process is a gold-gold contact point with high stability and longevity. Wires of the miniature slip ring rotor and stator use multi-color colored wires, and the wiring is simple. It is widely used in consumer electronics, small wind turbines, stage lights, etc. It can also be used in induction cookers, dining tables and other equipment that require large current and small size of the slip ring.

Specification

| Model | RDDLZ-M300A |

| Outer Diameter | 30mm |

| Rotating Speed | 250 rpm |

| Working Temp. | -30℃~80℃ |

| Working Humidity | 0~85% RH |

| Contact Material | gold-gold |

| Housing Material | plastic |

| Torque | 0.05N.m (+0.01N.m/6 circuits) |

| Working Life | 10 millions for ref (depends on working conditions) |

| Rated Voltage | 0~440VAC/VDC |

| Lnsulation Resistance | ≥300MΩ/300VDC |

| Lead Wire Spec. | refer to model list |

| Lead Wire Length | standard 200mm (can be customized) |

| Certification | CE, RoHS |

| Dielectric Strength | 300VAC@50Hz,60s |

| Electrical Noise | <0.01Ω |

| IP Grade | IP51 |

30mm Miniature Electrical Slip Ring (Type A Flange) Dimension Drawing

Standard Model List

| Model | Number of Circuit Wires | Max current/wire | Lead spec. | Length L (mm) |

| RDDLZ-M300A-0430 | 4 | 30A | AWG12#teflon, silver plated | 50 |

| RDDLZ-M300A-0250 | 2 | 50A | AWG12*2#teflon, silver plated | 50 |

| RDDLZ-M300A-0630 | 6 | 30A | AWG12#teflon, silver plated | 65.7 |

Color Code of Lead Wire

| ring # | 1 | 2 | 3 | 4 | 5 | 6 |

| color | BLK | BRN | RED | ORG | YEL | GRN |

Miniature Slip Ring Connector Installation Diagram

Tips: Faults and solutions in the use of miniature slip rings

- Short circuiting of the miniature slip ring after a period of use is possible due to the slip ring life. Another reason is that the slip ring is overloaded, causing the slip ring to burn out. In general, the short circuit of a new slip ring is caused by the problem of inner insulating material of the slip ring or direct short circuit between brush wire and brush wire, the wire is broken. This fault must be detected by the exclusion method.

- Signal interference of the miniature slip ring is too large. Slip rings can be used to transmit power and signals, and interference can occur between power supply and signal. The interference is divided into internal interference and external interference. Users must clearly know the type of signal during use. For special signals, use special wires to shield internal and external. For the slip ring that has been formed, when it is found that the slip ring signal is disturbed, users can shield the external wire by self.

- Miniature slip ring does not rotate smoothly. Excluding the problem of slip ring assembly and bearing selection, the cause of such problems is usually that the user does not propose shockproof requirements when selecting the slip ring. If the working environment has strong vibration, it will cause damage to the thin-walled bearings and cracking of the plastic spindle in the slip ring.

- IP grade of the miniature slip ring does not match the working environment. Normally, the slip ring IP grade is IP51. Some users put slip ring in the place with waterproof requirements without additional protection, causing water inside the slip ring to cause internal short circuit and causing the slip ring to fail.

- Miniature slip ring overload causes burnout. The allowed maximum current of the slip ring is the safely operable current value calculated based on the cross-sectional area, brush contact area, pressure of the brush and the contact surface, and rotational speed. If the current exceeds this value, the slip ring will be hot, or the contact surface will be ignited, even forming a solder joint between the brush and the slip ring. Although the slip ring will consider a certain safety factor during the production design phase, it is recommended that users provide the maximum current of actual application to slip ring manufacturers.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.