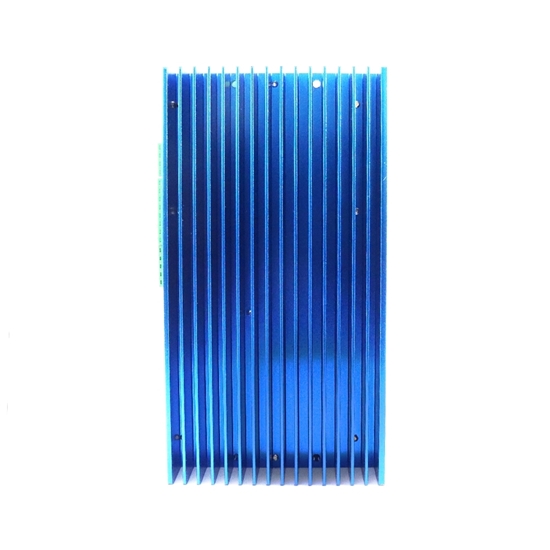

24V-60V Brushless DC Motor Controller For 24/36/48/60V BLDC Motor

from

$473.06

Ex Tax: $473.06

- Stock: In Stock

- Model: RDDLZ-BLDC-C100

- Weight: 1.00

- SKU: RDDLZ-BLDC-C100

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Brushless direct current motor controller with RS-485 communication design, low voltage and precise positioning control, adapts to BLDC motor control based on hall sensor, magnetic coding sensor and photoelectric coding sensor.

Specification

| Model | RDDLZ-BD100 (Click it to view more controller specs) |

| Matching Electric Motor Model | RDDLZ-BLDC-1500R3 (1.5 kW 36V/48V BLDC Motor) |

| RDDLZ-GEAR-W1500 (1.5 kW 36V/48V DC Worm Gear Motor) | |

| RDDLZ-GEAR-W2000 (2 kW 48V DC Worm Gear Motor) | |

| RDDLZ-GEAR-P1500 (1.5 kW 36V/48V DC Planetary Gear Motor) | |

| RDDLZ-GEAR-P2000 (2 kW 48V DC Planetary Gear Motor) | |

| Rated Current | 75A |

| Rated Input Voltage Range | DC +24~ +72V |

| Operating Temperature Range | -40-+80℃ |

| IO Input | Supports NPN, PNP |

| NPN: 0V is low, 5~24V is high, current 20mA | |

| PNP: 13V high output, low to ground | |

| IO Output | Open Drain NPN Output Voltage: not exceed 30V, Current: 500mA |

| SV Input Characteristics | DC 0-5V Range or DC 0-10V Range |

| Deadband Voltage Adjustment Range: 0.2~1.0V | |

| Input Internal Resistance:100k | |

| PWM Input Characteristics | Frequency Range: 1~10kHz (50% duty cycle) |

| Duty Cycle Range:0~100%(100Hz-1000Hz) | |

| Signal Voltage: DC 5~24V | |

| Carrier Frequency | 10~20kHz |

| 485 Communication Parameters | ID: 1~255 |

| Baud Rate: 9600/19200/38400/57600/115200 bps | |

| CAN Communication Parameters | ID: 0~255 |

| Baud Rate: 125/250/500 kbps | |

| Load | 150% of Rated Current |

| Overload Duration: 30~1s (at 150% Rated) | |

| External Temperature Sensor | Customizable |

| ntc=mf52-103f-3435-55l | |

| Control Method | Torque Loop (Open Loop) Speed Loop (Close Loop) |

| Acceleration and Deceleration Times | 0.5-16s Motor Without Load |

| Overheating Protection | Inside the Driver:+85℃ |

| Note* |

|

Dimensions (Unit: mm)

Note:

- Please install, connect, and debug the motor controller with industry technicians.

- It is not allowed to install, remove, or replace the circuit of the motor controller when it is live.

- Be sure to install necessary protective devices between the power input and the power supply (battery) to avoid dangerous accidents or fatal injuries.

- Need to install: overcurrent protector, insurance, emergency switch.

- Please do the isolation and insulation protection between the motor controller and the ground and equipment.

- If there is a real need for live debugging of this motor controller, please choose a non-metallic well-insulated screwdriver or special debugging tool.

- This motor controller shall be installed in a well-ventilated environment.

- This motor controller cannot be directly used in high humidity, dust, corrosive gas, or strong vibration of the abnormal environment.

Details

Tips: Brushless DC motor controller troubleshooting

The motor does not rotate.

- Insufficient voltage. Test whether the voltage of the third pin of the MCU exceeds 3.2V.

- Whether the brake level connection method is normal, check pin 7 of the MCU, the voltage of the high-level brake exceeds 2.5V, and the voltage of the low-level brake exceeds 2.0V.

- Whether the speed regulating voltage is added to the 5th pin of the MCU.

- The connector is improperly installed, and the output cannot be output due to lack of phase.

- When the above conditions are met, the output and drive circuit malfunctions, the external force forces the motor to rotate, and there is obvious uneven resistance inside, the MOS power tube is damaged, but some of the front-end drive transistors are damaged..

The motor rotates, but abnormal.

- Check whether the controller's working mode of 60 degrees and 120 degrees corresponds to it.

- The motor is the ability of external force, there is a loud operating sound when rotating, and the output is not stable. Check the condition of the connection line. The components of the circuit board have missing welding, virtual welding, short circuit, wrong welding, etc.

- Hall signal error, some motors need to adjust the output line and Hall signal line of the controller

- The motor is unstable when rotating at low speed, and the parameters of the drive circuit components are too different. Test whether the three-phase drive components are welded incorrectly, and the performance is different.

The motor is easy to stop and the load capacity is poor.

- Whether the controller short-circuit comparison resistance R9, R10 is 20K or 1.2K.

- Capacitor C7 (1000Pf), dead zone adjustment capacitor C24 (100PF) capacity deviation is too large

- Constantan wire is too long (When the capacity of the controller capacitor C7, C24 is wrong, the working current is abnormal, the general working current is large, and the constantan is too long)

- Some parts of the drive circuit are leaking and have poor performance.

The current-limiting resistor is heated, and the static current is too large.

- There is a short circuit in the detection circuit.

- Whether the driver output has a component welding error.

- Whether the connection in the plug-in corresponds.

Flammable MOS tube or motor runs normally at low speed, and when the handle rises quickly, the flammable MOS tube.

- Check whether the HC27 circuit (U3) normal.

- The voltage of pin 21 of the single-chip microcomputer is not the high level or low level of the logic check, and its pull-up resistance is open or soldered.

- The MOS drive signal cannot normally follow the output signal of the single-chip microcomputer, showing a normal level, and it is most likely to damage the MOS.

After adding the signal, the signal light goes out, but the motor does not rotate.

- Whether the motor output is well connected.

- The motor hall is not connected.

- The drive circuit has equipment open circuit or false soldering, missing soldering, etc.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.