- Stock: In Stock

- Model: RDDLZ-TST-25

- Weight: 1.00

- SKU: RDDLZ-TST-25

Available Options

Note: This steam trap cannot be used for drinking water.

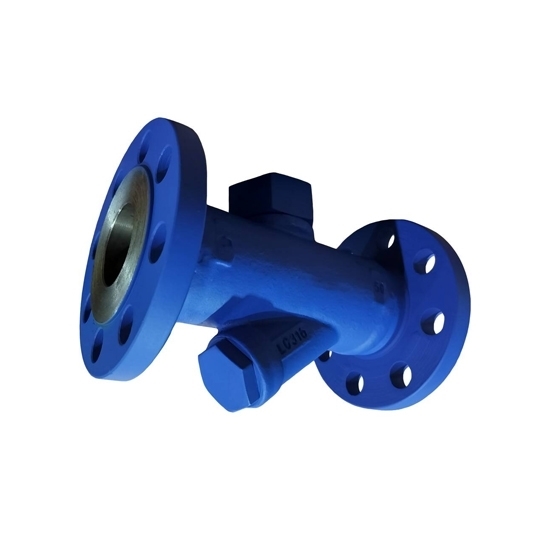

1 inch (DN25) thermodynamic steam trap is available with a strainer and trap. Quality disc steam traps feature steam or air insulation independent of ambient humidity and are suitable for applications with low or fluctuating steam pressures.

Specifications

- Model: RDDLZ-TD42F-16C-DN25

- Nominal Diameter: DN25 (1 inch)

- Connection Method: Flange

- Nominal Pressure: 1.6Mpa

- Max Work Temperature: 350℃

- Weight: 3.54kg

- Material: WCB

Features

- It has a steam or air thermal insulation device, which will not be affected by environmental humidity.

- Thermodynamic type steam trap is equipped with a filter and drain valve.

- It reduces the frequency of motion and lengthens the lifetime.

- A thermodynamic steam trap is sensitive and reliable in operation with a large capacity.

Dimension(Unit: mm)

| No. | Part Name | Material | |||||||

| 5 | Valve Cover | 2Cr13 | |||||||

| 4 | Valve Plate | SUS 440 | |||||||

| 3 | Valve Body | WCB | |||||||

| 2 | Filter | 304 | |||||||

| 1 | Screw Plug | 35 | |||||||

| DN | L | H1 | H2 | A | B | C | b | f | N~φ |

| 25 | 160 | 59 | 62 | 115 | 85 | 68 | 18 | 2 | 4~φ14 |

Applications

The thermodynamic steam trap is widely used in steam systems, particularly in applications where there is a high rate of condensate formation or where there is a need for rapid condensate removal. They are commonly used in processes such as steam heating, sterilization, and cooking, as well as in industrial processes such as chemical manufacturing and oil refining.

Tips: What can a steam trap do?

A steam trap is a device used to remove condensate and other non-condensable gases from steam systems while preventing the escape of live steam. Here are some of the things that a steam trap can do:

- Remove condensate: As steam travels through a steam system, it cools down and condenses into water. A steam trap removes this condensate and discharges it from the system, helping to maintain the proper temperature and pressure.

- Prevent live steam loss: Steam traps are designed to prevent the escape of live steam, which can be costly and inefficient. By keeping the steam in the system, the energy is conserved and can be used to power machinery or heat a facility.

- Protect equipment: Accumulation of condensate in a steam system can cause damage to the equipment, leading to downtime and repair costs. Steam traps remove the condensate and other non-condensable gases, protecting the equipment and ensuring optimal performance.

- Improve system efficiency: Steam traps help maintain the proper temperature and pressure in the steam system, improving overall efficiency. By removing condensate and non-condensable gases, steam traps ensure that the system is running at its best, reducing energy consumption and operating costs.

- Enhance safety: Steam traps help to prevent potentially dangerous situations, such as steam leaks or pressure build-up, which can pose a safety risk to workers and equipment.