- Stock: In Stock

- Model: RDDLZ-LE-AGD200

- Weight: 1.00

- SKU: RDDLZ-LE-AGD200

Available Options

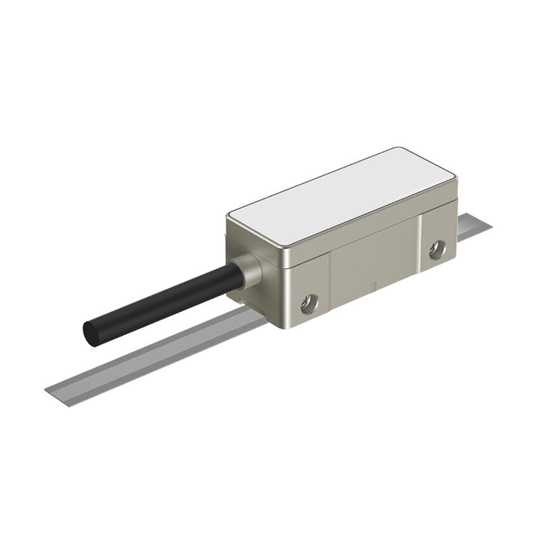

Absolute optical linear encoder delivers exceptional performance characteristics, offering a reliable solution for high-precision motion control and position measurement in diverse industrial and technological applications.

Features

- The absolute optical linear encoder features a reflective absolute optical system for accurate position detection.

- The absolute position encoder supports industry-standard interfaces like BISS-C or SSI.

- With high installation clearance, it facilitates easy setup in various environments.

- The optical linear encoder incorporates a high-precision measurement system to ensure accurate readings.

- The encoder utilizes a high flexibility, bending-resistant braided shielding wire for durability.

- Despite its compact size, it offers high resolution to meet demanding measurement requirements.

- Encased in a stainless steel shell, it provides strong anti-interference capabilities for reliable operation.

Specification

| Model | RDDLZ-AGD200 |

| Power supply | 5V±-10% |

| Current consumption | Less than 100mA |

| Resolution | 20~29bit |

| Accuracy level of grating ruler | ±5μm/m |

| Repeatability | ±1μm |

| Location data update rate | 80MHz |

| Output signal | Differential TTL |

| Mode of connection | Direct outlet, DB9 or DB15 |

| LED status | Red and green |

| Reading head size | 36mm*15mm*14mm |

| Grating scale size | 6mm wide (We can provide grating scale, please contact us) |

| Operating temperature | -10℃~70℃ |

| Storage temperature | -20℃~85℃ |

| Outside diameter of cable | 4.0±0.1mm |

| Number of bending | 50 million times, Bending radius greater than 24mm |

Dimension (mm)

Tips: Why do we need to use absolute linear encoders?

Absolute linear encoders are indispensable due to their ability to provide direct and accurate absolute position feedback without the need for initialization or referencing a starting point. This feature ensures precise positioning information is immediately available after power-up or system restart, crucial for applications requiring high precision and reliability. Their resistance to interference, long-term stability, and ease of integration further enhance their suitability across diverse industries such as CNC machining, medical imaging, and automated manufacturing, where precise measurement and control are paramount for operational efficiency and product quality.