- Stock: In Stock

- Model: RDDLZ-LP-AX300

- Weight: 1.00

- SKU: RDDLZ-LP-AX300

Available Options

45 kW stainless steel rotary lobe pump for sale, maximum outlet pressure 2 bar, rotor can be used for all types of pumps, lobe pump design is completely symmetrical, can change the direction of delivery by changing the drive direction.

Precautions for selection of rotary lobe pump

- Shaft power = flow Q (m3/h) x head H (Bar) / 36 / η.

- When the conveying medium is clear water, sewage and relatively dilute mud, the rotational speed n≤350rpm, when the conveying medium is dry mud, the rotational speed n≤100rpm.

- When it is necessary to ensure the self-priming height, the speed n is greater than or equal to 200rpm, when the equipment is running with gaps, such as mobile pump trucks, the speed can be greater than 350rpm.

- Different environments, different media, different speeds, please contact RDDLZ technicians.

- Other power lobe rotary lobe pumps can be customized.

Specification

- Model: RDDLZ-LP-AX300

- Power: 45 kW

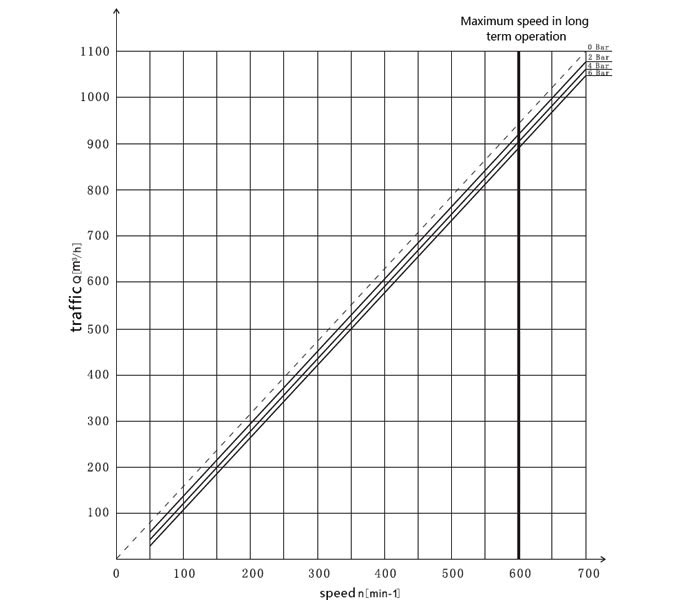

- Flow: 400~750 m3/h

- Maximum Outlet Pressure: 8 bar

- Maximum Speed: 600 rpm

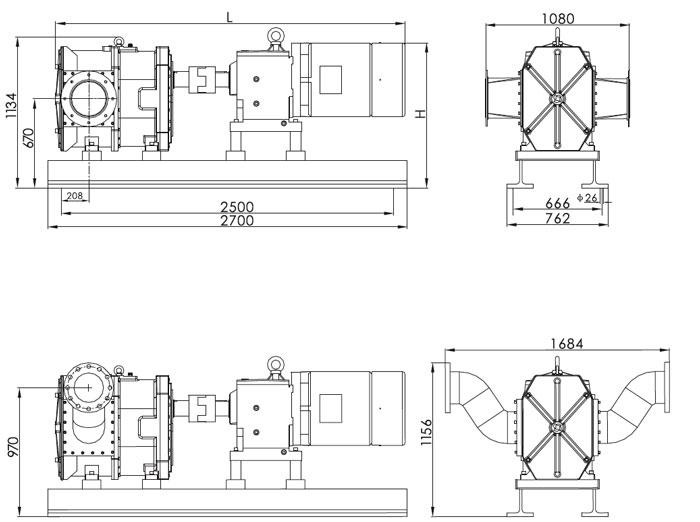

- Flange Diameter: DN200, DN250, DN300, DN350, DN400

- Weight: 2000 kg

- Dimension: 2688mm x 1005mm (L x H)

- Certificate: CE, ISO9000, ISO14000, ISO18000

Feature

- Strong self-priming ability, often used to replace submersible pumps or submersible pumps, the maximum suction stroke of the pump can reach 8.5-9.5 meters.

- The lobe pump has good wear resistance and is often used to transport fluid media containing impurities such as sludge, sewage, and slag.

- Simple maintenance, no need to dismantle the pipeline.

- Reversible operation, the design is completely symmetrical, and the conveying direction can be changed by changing the driving direction.

- No blockage, strong ability to pass impurities.

- Idling/dry running: the pump is insensitive to dry running, and short-term running will not cause damage to the pump.

- Energy saving and electricity saving, high efficiency.

- To solve the gas resistance, it can be mixed and conveyed with gas, liquid and slag.

- The overall operating cost of the pump is low.

- Ultra-wide medium viscosity conveying range, from low viscosity medium to high viscosity medium can be smoothly conveyed.

45 kW Rotary Lobe Pump Curve

45 kW Rotary Lobe Pump Installation Dimensions

Lobe Rotary Pump Applications

Tips: Rotary lobe pump troubleshooting

During the use of the rotor pump, if the flow pressure is insufficient, the motor is heated, the vibration noise, the bearing is heated, and the medium has air bubbles, the pump should be stopped immediately for inspection.

Insufficient flow pressure. The inlet seal is not good and needs to be re-installed; the rotor or cavity is worn, and the rotor or cavity is replaced.

The motor is hot. If the power supply is out of phase, reconnect the power supply, poor contact, excessive pressure and flow, adjust the pressure and flow, and check whether the current is overloaded; if the viscosity of the medium is too high, the heating medium should reduce its viscosity; the rotating parts are stuck in the pump, and the rotating parts should be replaced.

Vibration noise. The inlet is blocked, increase the inlet diameter, the pressure is too high or the vacuum is too high, and the vacuum degree or outlet pressure is reduced.

Leak at seal. The seal is too loose or damaged, adjust or replace the seal.

The pump is hot. If there is debris entering, the flow rate is too small or the pump is stuck. Open the pump cover, clear the debris, and check the rotation of the pump. If it is not normal, the wearing parts should be damaged.

Bearings are hot. The main shaft is bent, replace the main shaft, bearing, bearing damage, add lubricating oil. Insufficient oil storage in bearing oil chamber, refuel.

The medium has air bubbles. The inlet pipeline is leaking, check the inlet pipeline, connecting interface and valve.