New

Free Shipping

1 KW Rotary Lobe Pump

from

$13,598.76

Ex Tax: $13,598.76

- Stock: In Stock

- Model: RDDLZ-LP-AC50

- Weight: 1.00

- SKU: RDDLZ-LP-AC50

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Cost-effective rotary lobe pump power 1000W, maximum outlet pressure 10 bar, lobe pump has a compact structure, small shear force on the medium during conveying, and smooth operation with little vibration.

Precautions for selection of rotary lobe pump

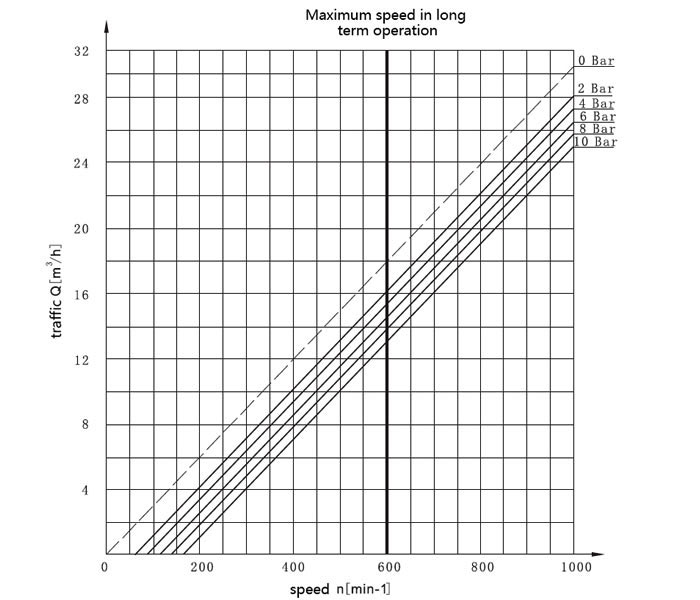

- Shaft power = flow Q (m3/h) x head H (Bar) / 36 / η.

- When the conveying medium is clear water, sewage and relatively dilute mud, the rotational speed n≤350rpm, when the conveying medium is dry mud, the rotational speed n≤100rpm.

- When it is necessary to ensure the self-priming height, the speed n is greater than or equal to 200rpm, when the equipment is running with gaps, such as mobile pump trucks, the speed can be greater than 350rpm.

- Different environments, different media, different speeds, please contact RDDLZ technicians.

- Other power lobe rotary lobe pumps can be customized.

Specification

- Model: RDDLZ-LP-AC50

- Power: 1 kW

- Flow: 3~8 m3/h

- Maximum Outlet Pressure: 10 bar

- Maximum Speed: 700 rpm

- Flange Diameter: DN40, DN50, DN65, DN80, DN100

- Weight: 93 kg

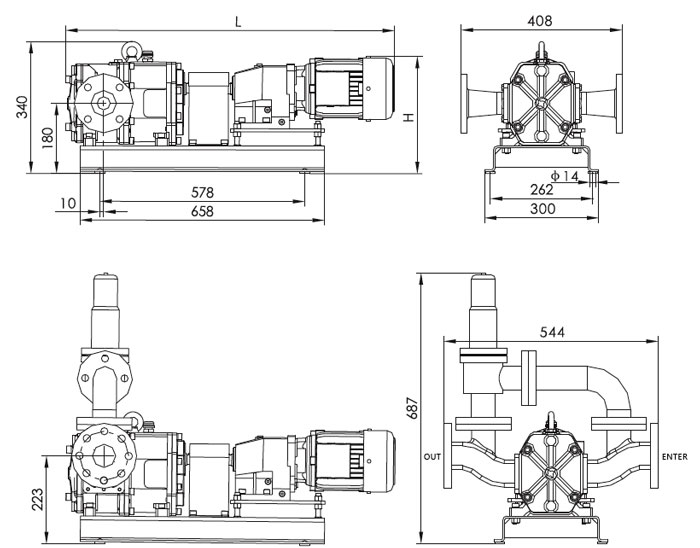

- Dimension: 990mm x 333mm (L x H)

- Certificate: CE, ISO9000, ISO14000, ISO18000

Feature

- Strong self-priming ability, often used to replace submersible pumps or submersible pumps, the maximum suction stroke of the pump can reach 8.5-9.5 meters.

- The lobe pump has good wear resistance and is often used to transport fluid media containing impurities such as sludge, sewage, and slag.

- Simple maintenance, no need to dismantle the pipeline.

- Reversible operation, the design is completely symmetrical, and the conveying direction can be changed by changing the driving direction.

- No blockage, strong ability to pass impurities.

- Idling/dry running: the pump is insensitive to dry running, and short-term running will not cause damage to the pump.

- Energy saving and electricity saving, high efficiency.

- To solve the gas resistance, it can be mixed and conveyed with gas, liquid and slag.

- The overall operating cost of the pump is low.

- Ultra-wide medium viscosity conveying range, from low viscosity medium to high viscosity medium can be smoothly conveyed.

1 kW Rotary Lobe Pump Curve

1 kW Rotary Lobe Pump Installation Dimensions

Small Rotary Lobe Pump Applications

Tips: RDDLZ Rotary lobe pump advantages

- Stainless steel rotors are available for all pumps, and some models offer rotors from PTFE.

- The rotors are machined via computer control, which ensures an exact geometry with small tolerances.

- For abrasive products, dual-vane, readjustable rotors are available.

With the helical screw lobe design, almost pulsation free conveying is achieved. - Wear-resistant pump casing in a one-piece block design are equipped with axial casing liners as standard and optional radial liners.

- The carrier- and synchronizing gear is in a separate sealed unit. The strong shafts and hardened gear wheels ensure high torque and power transmission.

- The high quality mechanical seals are suitable for high-pressure peaks and are easy to maintain.

- The intermediate chamber in between the synchronizing gear and the pump casing is filled with quench fluid. This fluid prevents any dry running of the mechanical seals and indicates possible seal leakage.

- The overall dimension sheets show the compact design with geared motors. For space-limited applications the drive can be fitted over the pump, with v-belt transmission. A complete aggregate for app. 150 m3/h (660 GPM) requires app. 1 m2 (10 ft2) only.

- Complete pump units are available with geared motors, variable speed geared motors, submersible drives or hydraulic motors. Even stationary or mobile units with combustion engines are available.

- Unlimited variations and applications.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.