- Stock: In Stock

- Model: RDDLZ-BLDC-C50

- Weight: 1.00

- SKU: RDDLZ-BLDC-C50

Available Options

BLDC motor driver is equipped with the basic control interface and the upper computer can realize the main functions of the whole system. The hall sensor motor can be controlled by square wave or positive wave algorithm.

Specification

| Model | RDDLZ-BD50 (Click it to view more controller specs) |

| Rated Current | 50A |

| Rated Input Voltage Range | DC +24~ +72V |

| Operating Temperature Range | -40-+80℃ |

| IO Input | Supports NPN, PNP |

| NPN: 0V is low, 5~24V is high, current 20mA | |

| PNP: 13V high output, low to ground | |

| IO Output | Open Drain NPN Output Voltage: not exceed 30V, Current: 500mA |

| SV Input Characteristics | DC 0-5V Range or DC 0-10V Range |

| Deadband Voltage Adjustment Range: 0.2~1.0V | |

| Input Internal Resistance:100k | |

| PWM Input Characteristics | Frequency Range: 1~10kHz (50% duty cycle) |

| Duty Cycle Range:0~100%(100Hz-1000Hz) | |

| Signal Voltage: DC 5~24V | |

| Carrier Frequency | 10~20kHz |

| 485 Communication Parameters | ID: 1~255 |

| Baud Rate: 9600/19200/38400/57600/115200 bps | |

| CAN Communication Parameters | ID: 0~255 |

| Baud Rate: 125/250/500 kbps | |

| Load | 150% of Rated Current |

| Overload Duration: 30~1s (at 150% Rated) | |

| External Temperature Sensor | Customizable |

| ntc=mf52-103f-3435-55l | |

| Control Method | Torque Loop (Open Loop) Speed Loop (Close Loop) |

| Acceleration and Deceleration Times | 0.5-16s Motor Without Load |

| Overheating Protection | Inside the Driver:+85℃ |

| Note* |

|

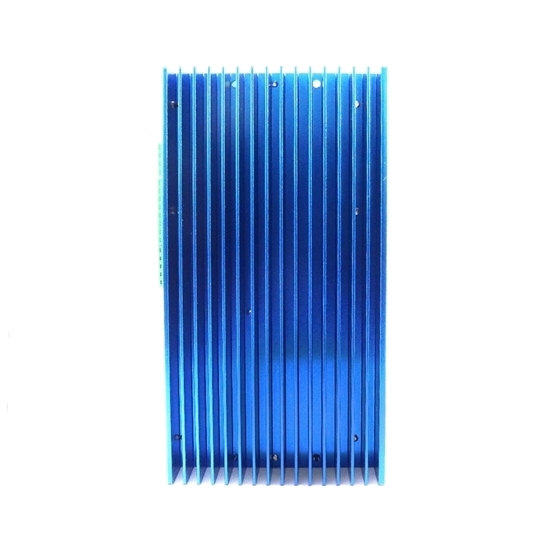

Dimensions (Unit: mm)

Note:

- Please install, connect, and debug the motor controller with industry technicians.

- It is not allowed to install, remove,e or replace the circuit of the motor controller when it is live.

- Be sure to install necessary protective devices between the power input and the power supply (battery) to avoid dangerous accidents or fatal injuries.

- Need to install: overcurrent protector, insurance, emergency switch.

- Please do the isolation and insulation protection between the motor controller and the ground and equipment.

- If there is a real need for live debugging of this motor controller, please choose a non-metallic well-insulated screwdriver or special debugging tool.

- This motor controller shall be installed in a well-ventilated environment.

- This motor controller cannot be directly used in high humidity, dust, corrosive gas, or strong vibration of the abnormal environment.

Details

Tips: What is a brushless DC motor controller?

The brushless DC motor controller is composed of the motor's main body and the driver. It is a typical mechatronic product. The BLDC motor drivers have the advantages of good adjustment and starting performance of the DC motor and the simple structure of the asynchronous motor without maintenance. The highly reliable motor speed regulation field has been widely used.

The motor controller is the command center for the normal operation of the brushless DC motor and the realization of various speed-regulating servo functions. It mainly completes the following functions: logically synthesize various signals to provide various control signals to the drive circuit; generate PWM modulation signals, realize the speed regulation of the motor, adjust the speed of the motor to the current loop, so that the system has better dynamic static performance, and realize the fault protection functions such as short circuit, over current, under voltage, and locked rotor.