- Stock: In Stock

- Model: RDDLZ-CC-6018

- Weight: 1.00

- SKU: RDDLZ-CC-6018

Available Options

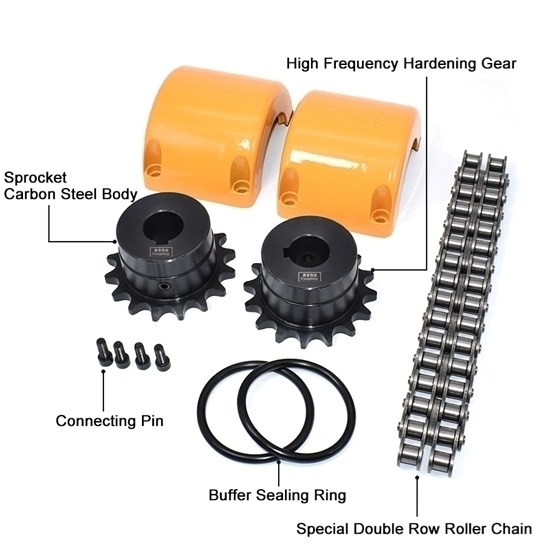

The 16-45mm roller chain coupling is lightweight, small in size, and can be used in a variety of applications without moving both shafts during disassembly. A lightweight roller chain shaft coupling has high torque capacity which provides reliable performance in high speed and wet environment.

Specification

| Model | RDDLZ-KC-6018 | |

| Chain Model | 60-2x18 | |

| Min Hole Diameter | 16 | |

| Max Hole Diameter | 45 | |

| Dimension | A | 142 |

| d | 85 | |

| O | 127 | |

| L | 123.5 | |

| I | 56 | |

| S | 11.5 | |

| B | 105 | |

| C | 22.8 | |

| Bolt | 10M | |

| Max Torque | 1810 Nm | |

| Max Speed | 2500 rpm | |

| Moment of Inertia | 137.3 kg.cm2 | |

| Weight | 6.2kg | |

Features

- Chain shaft coupling provides direct power transmission between two components without any slip or play, which contributes to efficient power transmission and reduced energy loss.

- 16 to 45mm chain coupling can accommodate a certain degree of misalignment between the shafts of the two components it connects.

- Chain couplings are designed to absorb shock loads and vibrations that may occur during operation, which helps to protect the components and extend their life.

- The roller chain coupling has a simple structure and is easy to install and disassemble, without moving the two coupled shafts.

Dimension (unit: mm)

Applications

Chain couplings are commonly used in industrial applications where there is a need to transmit power between two rotating shafts. They are known for their high torque capacity and durability, and are often used in applications where there are large axial and radial misalignments between the shafts. Chain coupling is widely used in various industries, including automotive, aerospace, and manufacturing.

Tips: How to choose the right chain coupling for my application?

- Load capacity: The first thing you should consider is the load capacity of the coupling. This refers to the maximum load that the coupling can handle without failing. To determine the load capacity, you should consider the maximum torque and horsepower requirements of your application.

- Shaft diameter: The coupling should be able to fit the shaft diameter of your application. Make sure to measure the diameter accurately to ensure a proper fit.

- Misalignment: Consider the type and amount of misalignment that your application may experience. Chain couplings are designed to accommodate different types of misalignment, such as angular, parallel, and axial misalignment.

- Speed: The speed of your application can also affect the selection of the coupling. Make sure to choose a coupling that is suitable for the operating speed of your equipment.

- Environment: Consider the environmental conditions in which your equipment will operate. This includes factors such as temperature, humidity, and exposure to chemicals or other corrosive substances. Choose a coupling that is designed to withstand the specific conditions of your application.

- Maintenance: Some chain couplings require more maintenance than others. Consider the level of maintenance required for each coupling and choose one that fits your maintenance schedule.

- Cost: Finally, consider the cost of the coupling. While it's important to choose a coupling that meets your requirements, you should also consider your budget and choose a coupling that is cost-effective.

By taking these factors into consideration, you can choose the right chain coupling for your application that will provide reliable and efficient performance.