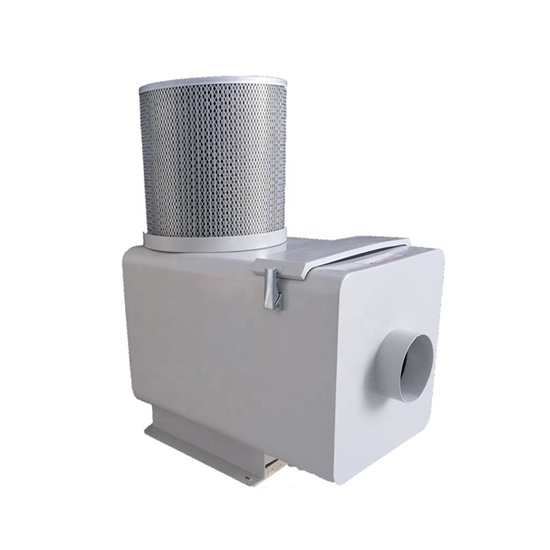

2 Hp (1500W) Oil Mist Eliminator, 1500Pa, 1200 M³/h

from

$934.77

Ex Tax: $934.77

- Stock: In Stock

- Model: RDDLZ-OME-YQ1500

- Weight: 1.00

- SKU: RDDLZ-OME-YQ1500

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Oil mist eliminators play an important part in the extraction and filtration of oil mist. With a 1500W three-phase motor as power supply, the machine can present remarkable performance while ensuring stable operation. A considerable air volume up to 1500Pa brings about impressive fume collection capability, in addition to which, the purifier also features low noise (65dB) and sufficient blast volume (1200 m³/h).

Specifications

| Model | RDDLZ-OME-DER-YQ1500 |

| Voltage | 380V (three-phase) |

| Power | 1500W |

| Wind Pressure | 1500Pa |

| Air Volume | 1200 m³/h |

| Noise | 65dB |

| Efficiency | 99% |

| Diameter of inlet | 200mm |

| Diameter of outlet | 14mm |

| External dimension | 677*420*513mm |

| Installation dimensions | 367*372mm |

| Weight | 55Kg |

Product structure diagram

Tips: Kind reminder for selection of oil mist eliminators

Oil mist eliminators are generally applied for dealing with the oil mist and water mist produced during metal processing where cutting oil, emulsion and synthetic coolant are used.

- The filter element serves as an essential inner component of oil mist filters as it determines the filtering capacity of the latter. The filtration efficiency of a filter element is generally no less than 99.97% (0.3um). On this account, YQ series of oil mist eliminators are equipped with HEPA filters which raise the purification rate up to 99.997% and above.

- The oil mist eliminator of which the intelligent control system has a high degree of automation is recommended in that the intelligent control system is able to maintain a constant flow rate in light of the clogging and working condition of the filter element and if clogging indeed happens, the system will sound the alarm to remind the user to replace the filter element.

- The air volume should be coordinated with the suction in an oil mist eliminator. The blast engine works as the power system of eliminators which means it should provide sufficient flow rate in order to sweep out fume and dust and meanwhile adequate suction is necessary to overcome the resistance from the filter element as well as tubes.

- The noise should be low and the vibration should be small. The noise and vibration are mainly caused by the blast engine and the air flow. Therefore, quality blast engines are characterized by a well-designed volute structure which has a smooth surface and is helpful for the impeller to achieve dynamic balance, thus reducing the noise and vibration to a degree.

- Special emphasis should be placed on the overall structure of the oil mist eliminator by reason that an appropriate structure can not only lower the noise but also prevent premature clogging of the filter element and facilitate the replacement of it.

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.