- Stock: In Stock

- Model: RDDLZ-HOP-2HP

- Weight: 1.00

- SKU: RDDLZ-HOP-2HP

Available Options

A 2 hp hot oil centrifugal pump is a mechanical device designed to circulate and transfer heat-conductive oil or thermal fluids within industrial processes that require precise temperature control. Constructed from materials that can withstand high temperatures and thermal expansion, oil transfer pump often feature components like high-temperature seals and specialized bearings to ensure durability and reliability.

Features:

- Corrosion Resistance. Pumps used for hot oil applications are typically made from materials that resist corrosion, ensuring the longevity of the pump in harsh operating conditions.

- Robust Construction. Hot oil pumps are built to be robust and durable, with materials chosen to withstand the thermal stresses associated with high-temperature operations.

- Efficiency. Hot oil pumps are engineered for high efficiency to minimize energy consumption while effectively circulating the heat transfer fluid through the system.

Specification:

- Model: RDDLZ-RY25-25-160

- Voltage: 380V

- Power: 2 HP (1.5 kW)

- Material: cast iron

- Head: 27m

- Flow Rate: 3 m3/h

- Speed: 2900 r/min

- Efficiency: 30%

- Motor: 90S

- Seal Method: packing seal

- Working Temperature: -20 ℃ ~ 350℃

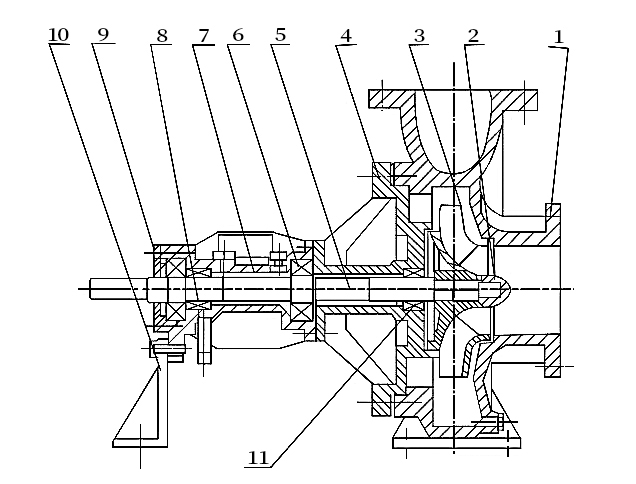

Structure:

| 1. Pump Casing | 2. Impeller Nut | 3. Impeller | 4. Pump Cover |

| 5. Pump Shaft | 6. Bearing | 7. Bearing Casing | 8. Oil-conducting Pipe |

| 9. Bearing's Press Cover | 10. Bear Frame | 11. Packing Seal |

Application:

Tips: What are the disadvantages of hot oil pump?

Hot oil pumps have several disadvantages, including high operational costs due to the need for specialized materials that can withstand high temperatures. They require meticulous maintenance to prevent leaks and ensure safety, which adds to operational expenses. The potential for thermal degradation of the oil over time can lead to efficiency losses and necessitate frequent oil changes. Additionally, these pumps pose significant safety risks, such as fire hazards, due to the high temperatures involved. The complexity of their design and the need for precise temperature control further complicate their operation and increases the likelihood of mechanical failures.