- Stock: In Stock

- Model: RDDLZ-UlTC-060S

- Weight: 1.00

- SKU: RDDLZ-UlTC-060S

Available Options

Features

- Stainless steel tank, high durability and long service life.

- Large capacity tank holds 15 litre volume, capable of cleaning many items at one time.

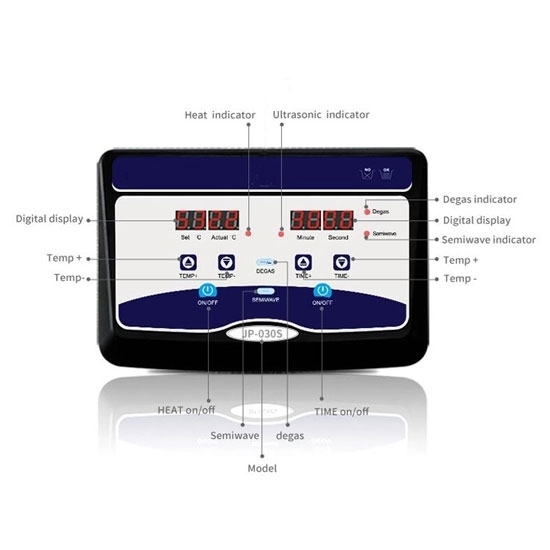

- Ultrasonice cleaning machine has digital timer control, 0-30min adjustable.

- With digital heating function range of 20°C ~ 80°C, helpful to remove the oil and wax.

- Degas function to prevent the items from oxidation.

- Dual ultrasonic power 180W/360W to meet different cleaning requirements.

- Ultrasonic cleaner comes with stainless steel basket to keep the items secure.

- Using only tap water, or industrial alcohol and solvent cleaner for higher cleaning requirement.

- Adopting industrial control chip microcontroller, flexible circuit board control, safer and more stable.

Specification

| Model | RDDLZ-JP-060S |

| Tank Capacity | 15L |

| Transducer Quantity | 6 |

| Ultrasonic Power | 180/360W |

| Heating Power | 300W |

| Timer | 1~30 min adjustable |

| Heating Temperature | 20℃~80℃ adjustable |

| Ultrasonic Frequency | 40kHz |

| Power Supply | AC 110V 60Hz or AC 220V 50Hz |

| Material | Stainless Steel SUS304 |

| Tank Size | 330*300*150mm (L*W*H) |

| Product Size | 400*350*280mm (L*W*H) |

| Net Weight | 10kg |

| Gross Weight | 11kg |

| Certification | CE, RoHS |

| Warranty | 1 Year |

| Document | Download Ultrasonic Cleaner User Manual |

Applications

- Jewelry Industry: Jewelry, diamond, gold, silver products

- Machinery: Moulds, precision parts, pressing parts, camera parts, bearing, hardware tools

- Electronics: PCB board, electronic parts, TV parts, computer parts

- Auto Industry: Engine parts, gear box, shock absorber, auto nozzle, cylinder, valve

- Dental& Medical: Dental tools, medical tools, injector, surgery tools, dropper, glass container

- Plating& painting: Polishing parts, SUS cutter, tableware, plating

- Food industry: Oven tray, boiler, bottles, bottle cap, filters

- Optical& watch maker: Optical lens, eyeglass, metal, gold, jewelry, diamond, watch band, watch cover, watch hand

- Textile: Spinneret plate, rubber parts, plastic molds, toy

- Others: Seal, flapper, coins, pottery, bank card, IGBT

Tips: Notes for Use of Ultrasonic Cleaner

1. The power supply and the heater power supply must be well grouding.

2. Do not start the ultrasonic cleaner when there is no water or solvent in the tank, otherwise it will cause empty vibration, causing damage to the vibration head or scrap.

3. The ultrasonic cleaner with heating system is strictly prohibited to turn on the heating switch when there is no liquid.

4. The bottom of the washer should be rinsed regularly, without excessive sundries or dirt.

5. Do not put your finger into the cleaning tank during the operation of the cleaner, or you will feel tingling or discomfort.

6. When changing new liquid every time, wash the parts after ultrasonic starting.

7. Clean water or aqueous solution shall be used as cleaning agent. Alcohol, gasoline or other corrosive, flammable and explosive liquids can not be used as cleaning agent to be added into the cleaner, which may cause fire and other dangerous situations.

8. When corrosive or volatile cleaning solution is needed, indirect cleaning method can be used. That is, firstly add water into the cleaning tank, and then pour the required cleaning liquid into the appropriate container and put the items to be cleaned; after that, place the container containing cleaning liquid and cleaning substances immersed in the cleaning tank, and then start cleaning work.

9. Try to avoid working continuously for a long time, generally no more than 30 minutes. After each use, the cleaner should be shut down more than 20 minutes to restart the use.

10. In use, the cleaning liquid or degassing solvent in the cleaning tank should not be put too little, at least should be in the tank more than 1/2, generally in the tank 2/3 appropriate.